1. Material selection:

The heart of a stainless steel saw blade lies in its material selection. Materials such as high-speed tungsten-molybdenum alloy steel or high-speed tungsten-molybdenum cobalt-containing alloy steel are the first choice due to their excellent hardness and wear resistance. These materials can achieve a certain toughness through specific alloy ratios and heat treatment processes while ensuring sufficient hardness of the saw blade. The balance of hardness and toughness ensures that the saw blade can withstand large pressure during high-speed cutting and is not easy to break.

2. Heat treatment technology:

Heat treatment technology is critical to the hardness and toughness of stainless steel saw blades. Quenching treatment can significantly increase the hardness of the saw blade, making it less likely to wear when facing hard materials; while tempering treatment can reduce the hardness to a certain extent, increase toughness, and prevent the saw blade from breaking when impacted. By precisely controlling the temperature and time of quenching and tempering, the best balance of hardness and toughness can be achieved.

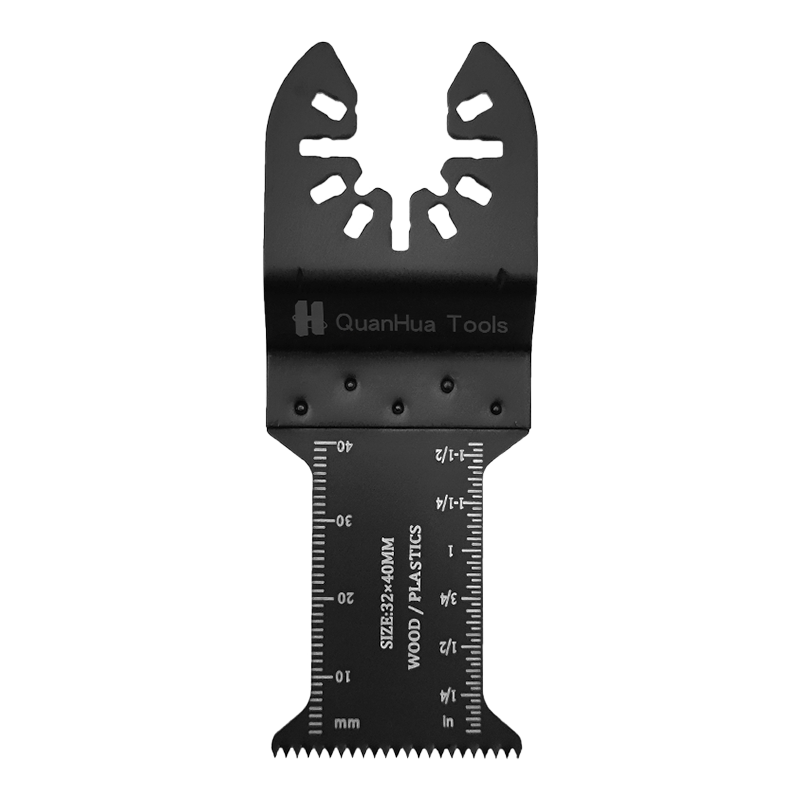

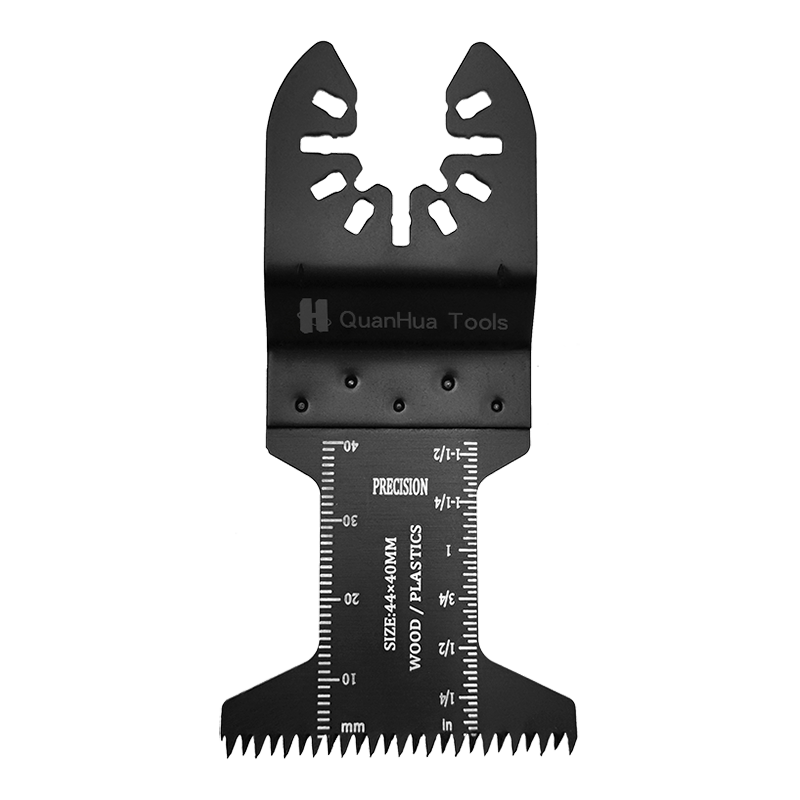

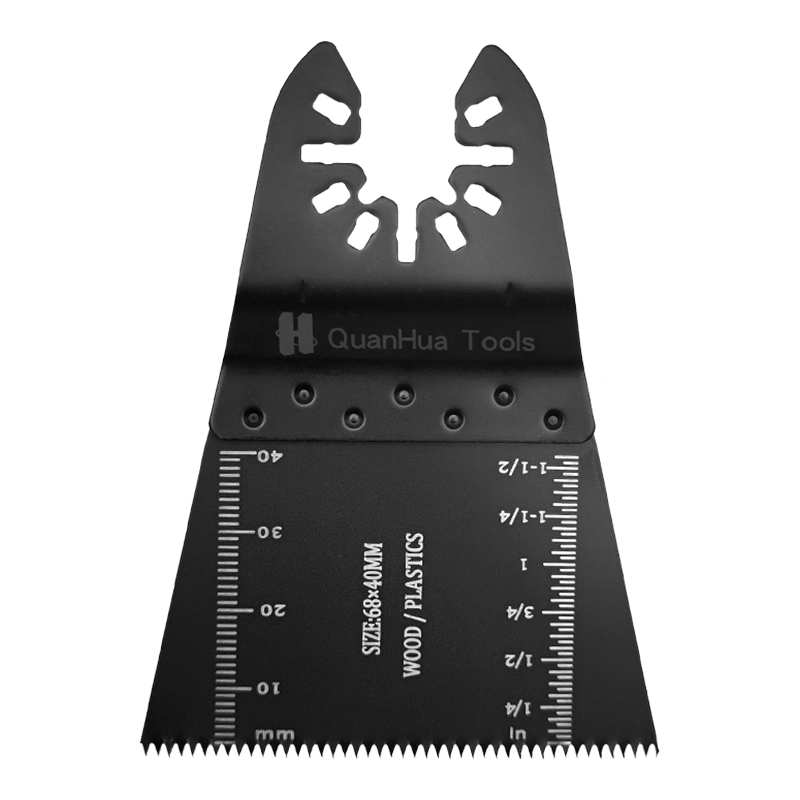

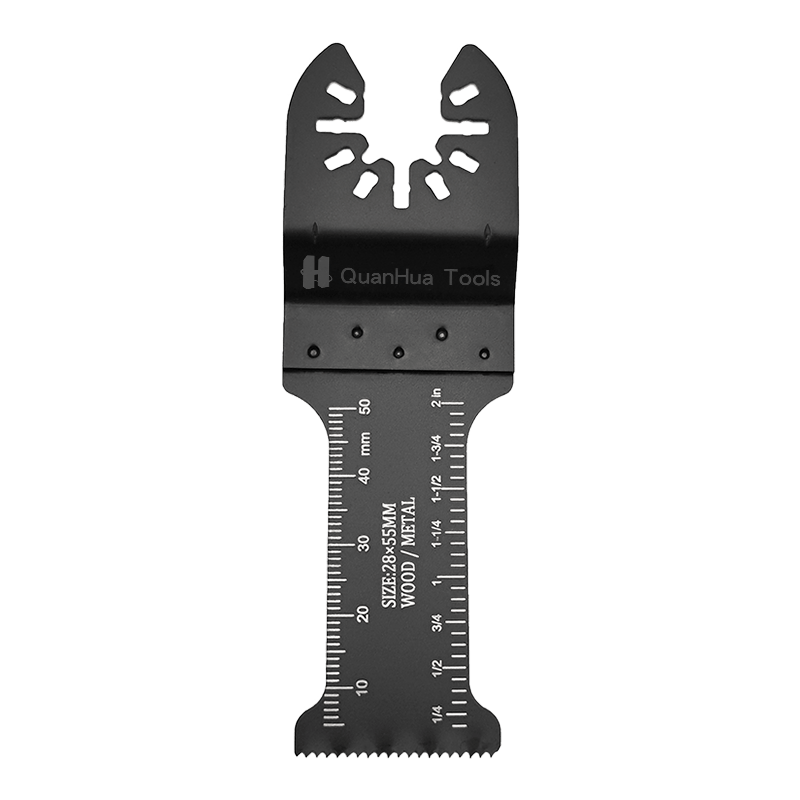

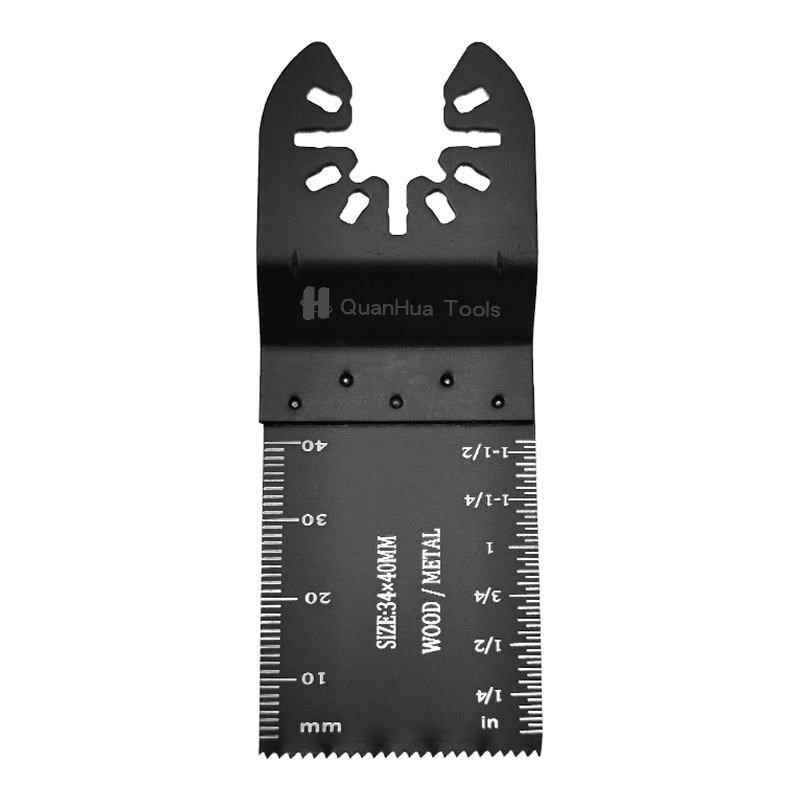

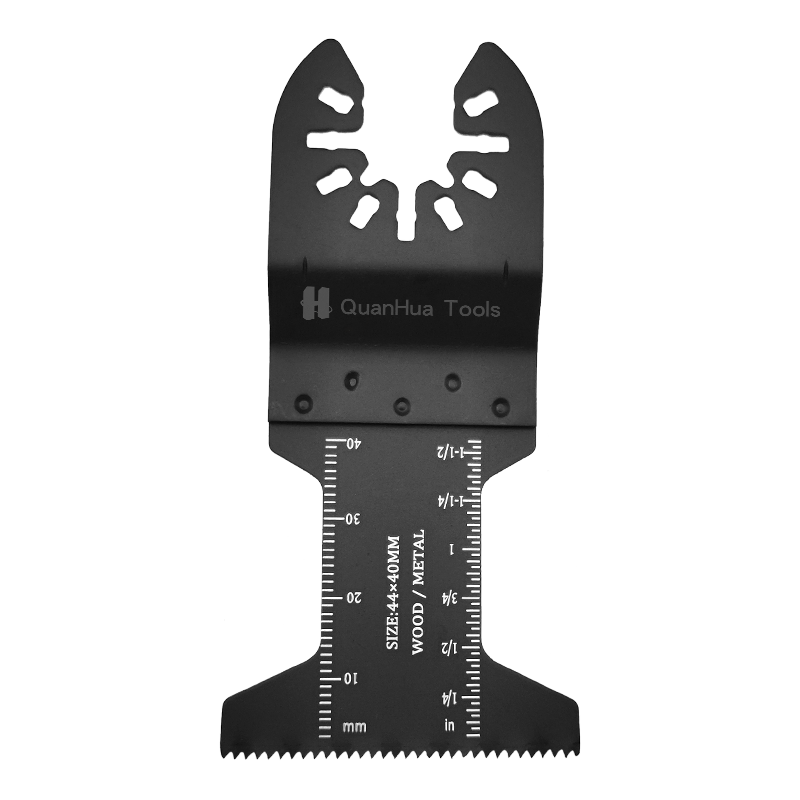

3. Sawtooth design:

The design of the saw teeth has a significant impact on the cutting performance and hardness-toughness balance of the stainless steel saw blade. Reasonable sawtooth shape and angle can reduce cutting resistance and improve the stability and wear resistance of the saw blade. At the same time, appropriate tooth pitch design can also ensure that the saw blade is evenly stressed during the cutting process and avoid breakage caused by excessive local stress. Therefore, during the sawtooth design process, the hardness and toughness properties of the material need to be fully considered to achieve the best balance.

4. Coating technology:

Coating technology is an effective means to improve the hardness and wear resistance of stainless steel saw blades. By coating the surface of the saw blade with a wear-resistant and corrosion-resistant coating, such as chromium nitride alloy coating, oxide coating, titanium gold coating, etc., the hardness and wear resistance of the saw blade can be significantly improved. At the same time, these coatings can also increase the toughness of the saw blade to a certain extent and prevent it from breaking due to impact during use. Therefore, when selecting and using coating technology, its impact on hardness and toughness needs to be considered comprehensively.

5. Manufacturing process:

The manufacturing process also has an important impact on the hardness and toughness balance of stainless steel saw blades. The use of advanced manufacturing processes and equipment, such as precision grinding, laser cutting, etc., can ensure the dimensional accuracy and surface quality of the saw blade. This not only helps to improve the hardness and wear resistance of the saw blade, but also increases its toughness to a certain extent. Therefore, various process parameters need to be strictly controlled during the manufacturing process to ensure that stainless steel saw blades that meet the requirements are produced.

55 TEETH STAINLESS STEEL HORSE KNIFE SAW BLADE FOR BONE CUTTING QH-MDJ-S906

The blade boasts 55 finely honed teeth, providing a remarkable cutting edge for bone materials. This tooth configuration ensures smooth, clean cuts while minimizing bone dust and debris. Crafted from high-quality stainless steel, this blade exhibits good corrosion resistance, ensuring longevity and reliability even in challenging, high-moisture environments. The 55-Tooth Sabre Saw Blade's unique design allows for precision and speed in cutting bone without excessive effort. This makes it an indispensable tool for those who demand efficiency in their work.