Cutting Metal with Carbide Oscillating Multitool Saw Blades

Material Composition and Durability

Carbide blades are manufactured from tungsten carbide, a material known for its exceptional hardness and resistance to wear. This makes them particularly effective for cutting through tough materials, including various types of metal such as steel, stainless steel, copper, and aluminum. The carbide teeth maintain their sharpness longer than standard steel blades, allowing for consistent performance over extended periods.

Types of Metal Cuts

Carbide oscillating blades are adept at making a variety of cuts in metal:

Straight Cuts: Ideal for trimming and shaping metal sheets or pipes.

Plunge Cuts: Useful for cutting into metal surfaces to create openings or slots.

Flush Cuts: Perfect for trimming metal protrusions flush with surrounding surfaces.

Speed and Efficiency

These blades operate at high oscillation speeds, allowing for rapid and efficient cutting. The oscillating action reduces the risk of overheating, which can be a problem with continuous cutting methods like grinding. This makes carbide blades suitable for repetitive cutting tasks without compromising performance.

Versatility Across Materials

One of the significant advantages of carbide blades is their ability to cut through mixed materials. For instance, if a project involves both metal and wood, a carbide blade can seamlessly transition between cutting metal studs and wooden beams without needing a blade change. This versatility is particularly beneficial in construction, remodeling, and repair tasks.

Precision and Control

The design of carbide oscillating blades allows for precise control, essential for detailed and intricate cuts in metal. The fine, sharp teeth enable clean, accurate cuts, reducing the need for extensive finishing work. This precision is crucial when working on tasks that require exact dimensions and smooth edges, such as metal fabrication or automotive repair.

Compatibility and Ease of Use

Carbide oscillating blades are compatible with most oscillating multitool brands, making them a convenient addition to any toolkit. Their ease of attachment and detachment allows for quick blade changes, enhancing productivity and minimizing downtime during projects.

Practical Applications

Plumbing

Plumbers use carbide oscillating blades to cut through metal pipes, including copper and galvanized steel. The blades make it easy to fit pipes to the required lengths and shapes, facilitating installations and repairs.

Automotive

In automotive repair and restoration, carbide blades are used to cut through metal panels, exhaust pipes, and bolts. The precision of these blades is invaluable for tasks that demand careful cuts to avoid damaging surrounding components.

Construction and Remodeling

Contractors and DIY enthusiasts use carbide blades for cutting metal framing, rebar, and fasteners. The ability to cut both metal and other materials without changing blades saves time and effort.

Metal Fabrication

Metalworkers utilize carbide oscillating blades for detailed fabrication tasks, including cutting, shaping, and fitting metal components. The blades' durability ensures they can handle the rigorous demands of fabrication work.

Maintenance and Safety

Blade Maintenance

Regular inspection and maintenance of the blades are crucial to ensure longevity and performance. Cleaning the blades after use and storing them properly prevents rust and buildup that could affect cutting efficiency.

Safety Precautions

When cutting metal, it is essential to wear appropriate safety gear, including gloves, safety glasses, and hearing protection. Ensuring the workpiece is securely clamped will prevent movement and potential accidents. Additionally, operating the tool at the recommended speed for the material being cut will enhance safety and effectiveness.

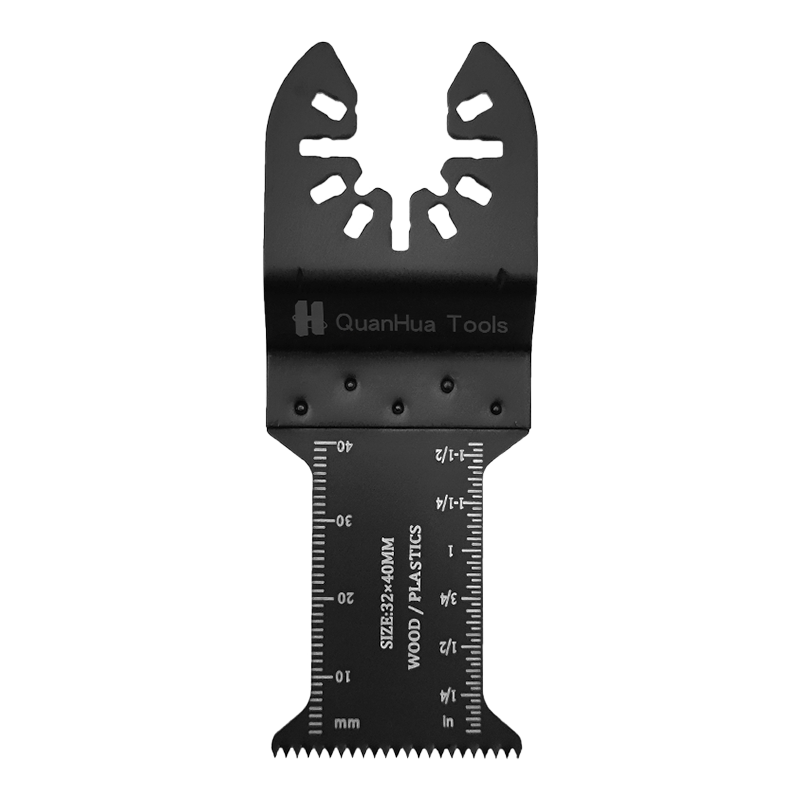

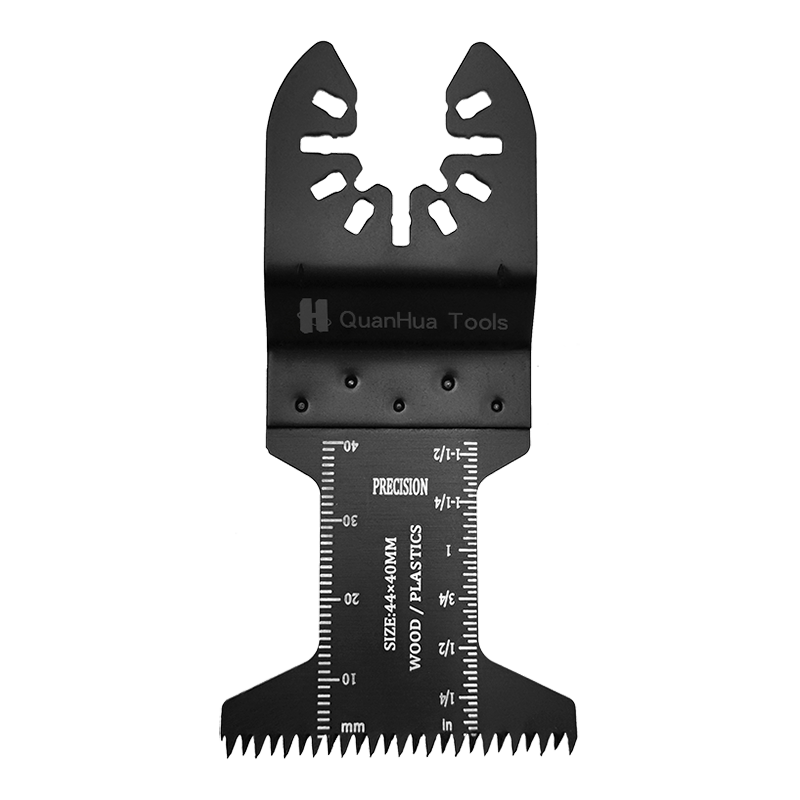

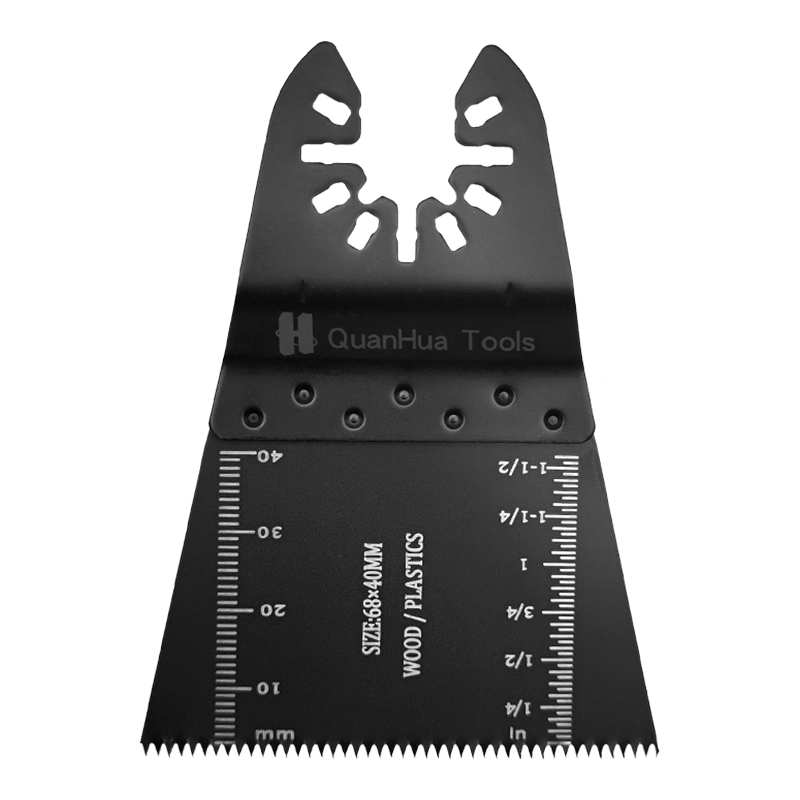

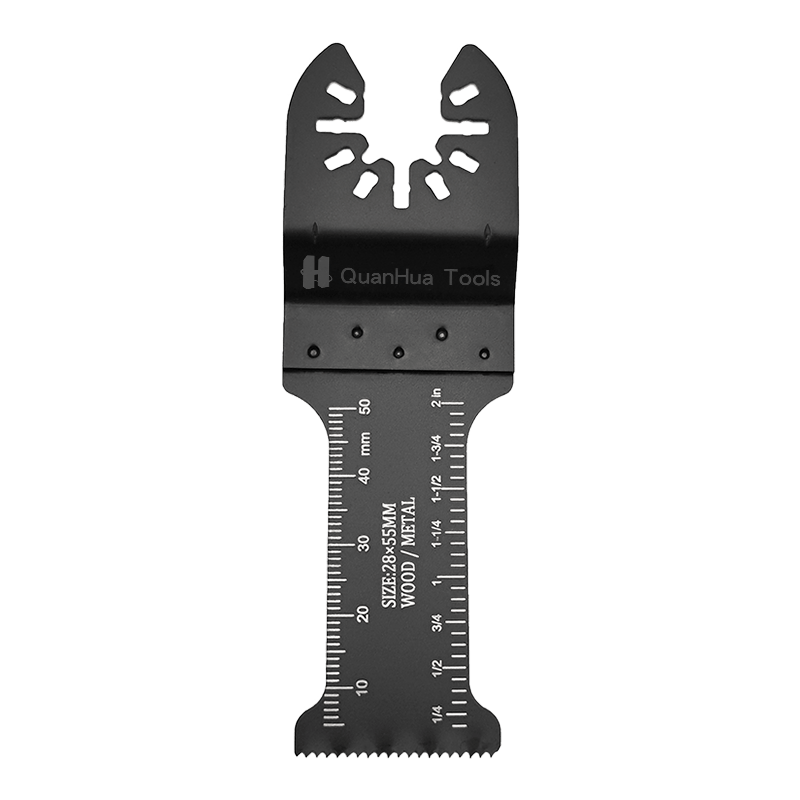

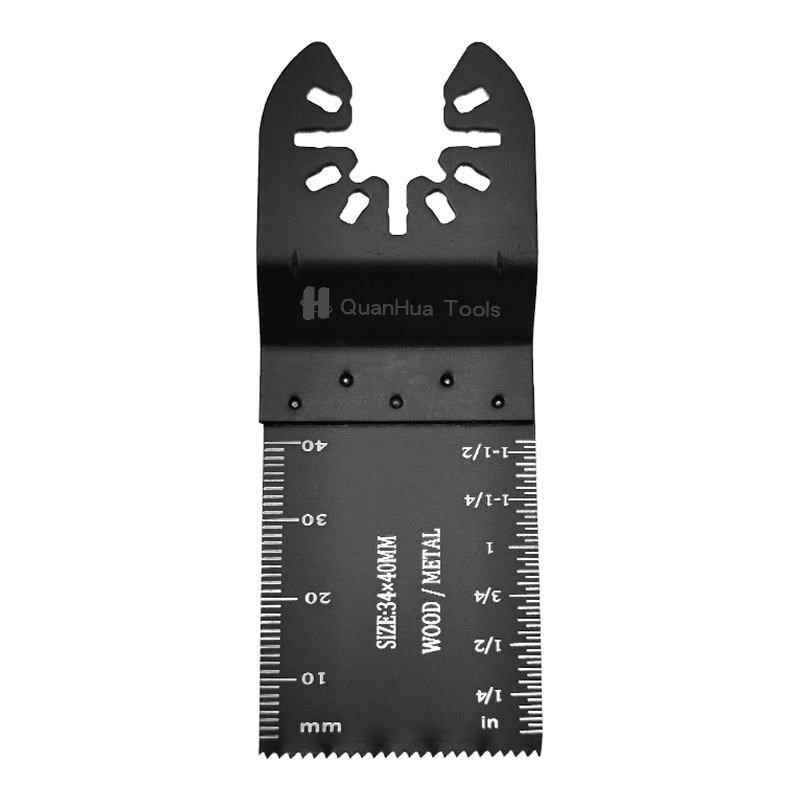

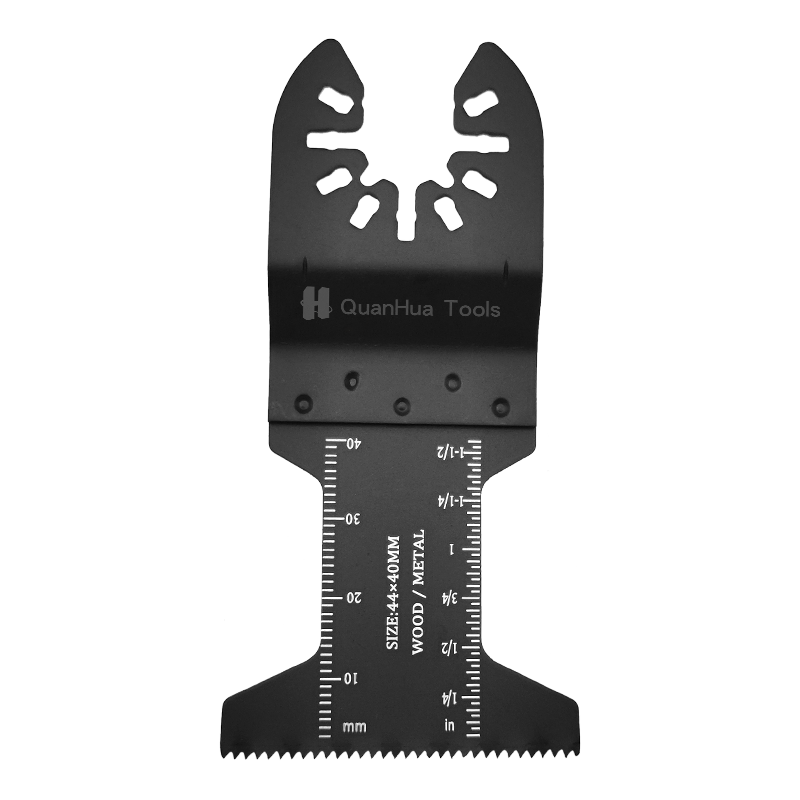

Steel Nail Cutting Hard Alloy Horse Blade Saw Blade QH-MDJ-A606

The Sabre saw blade, designed for precision cutting of hardened steel nails, constructed from high-quality materials that ensure exceptional durability, even when used on hardened steel. This longevity minimizes the need for frequent replacements, saving you time and money. Its unique tooth design and cutting edge geometry are optimized for cutting through hardened alloys with ease. The blade's sharp teeth make swift work of steel nails, reducing effort and increasing efficiency. This saw blade is not limited to steel nails alone. It can also be used for cutting through various materials, such as wood, plastic, and non-ferrous metals, making it a multi-purpose cutting solution.