1. Choose the right Starlock adapter

Choosing the right Starlock adapter is a critical step in ensuring that your machine and saw blade are compatible. Starlock adapters come in a variety of models and sizes to accommodate different saw blade types and machine configurations. When choosing an adapter, first consider the specifications of the saw blade, including its diameter, aperture, and the required mounting method. Secondly, you also need to check the specifications of the machine's spindle or adapter seat to ensure that the adapter can be securely mounted on the machine. Adapters usually have detailed technical specifications that can be used to select the most suitable model. The correct selection of adapters not only improves the efficiency of saw blade use, but also reduces equipment damage or operating problems caused by incompatibility. When choosing, it is more practical to choose a multi-functional or universal Starlock adapter considering that you may need to change saw blades or use different types of saw blades in the future.

2. Install the adapter

The process of installing a Starlock adapter on a common universal machine is usually very simple, but there are some basic steps to follow. First, align the adapter with the machine's spindle or adapter seat to ensure that the interface is properly docked. Then, use the appropriate tool or manual method to fix the adapter in place, depending on the design requirements of the adapter. Modern Starlock adapters are often designed with quick installation mechanisms, such as a locking system, which can be quickly and securely fixed to the machine, reducing the complex operation steps common in traditional installation methods. Make sure every step of the installation process is accurate and correct to avoid equipment failure or unstable saw blade operation due to improper installation. After installation, check whether the adapter is firmly connected to the machine to ensure that there is no looseness or misalignment, which is crucial to ensure the stability of the saw blade during operation.

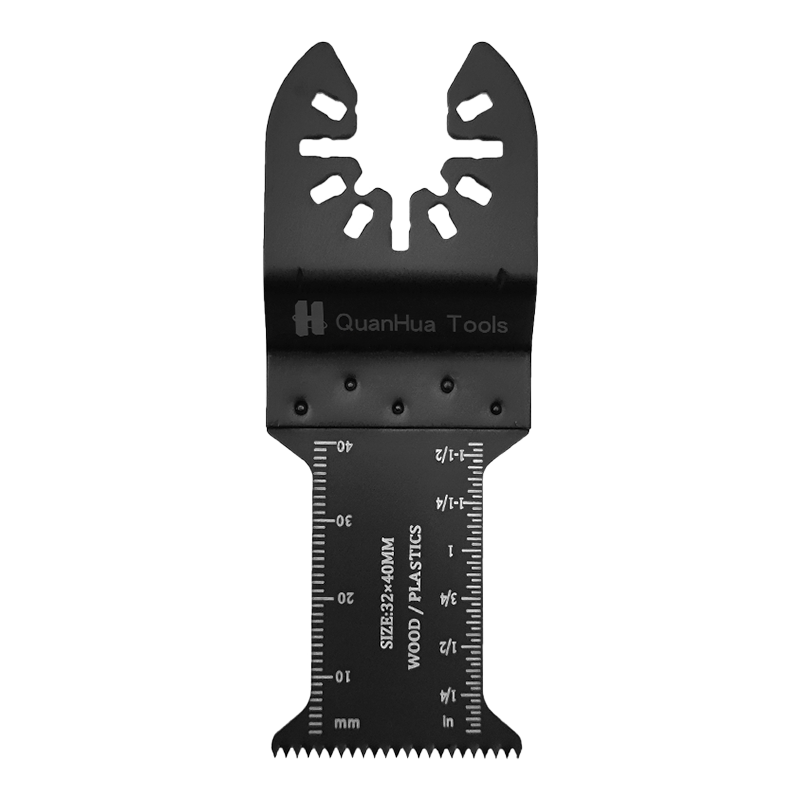

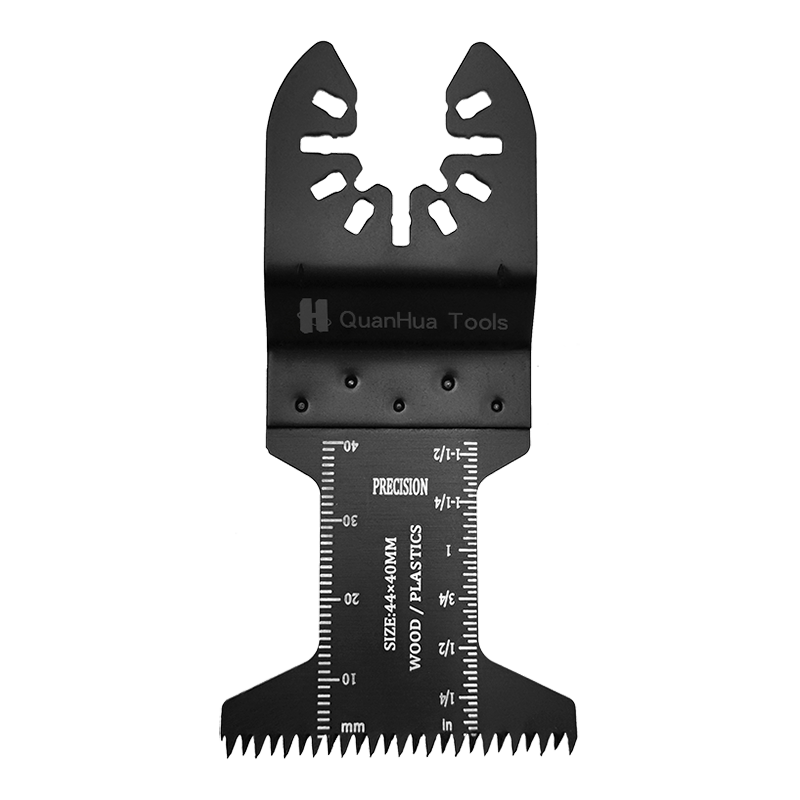

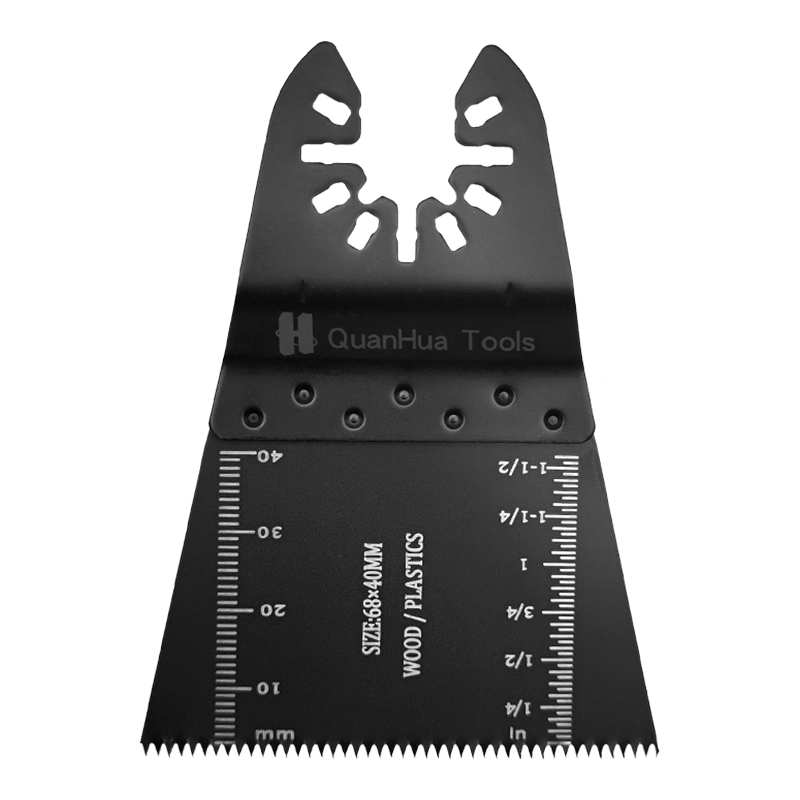

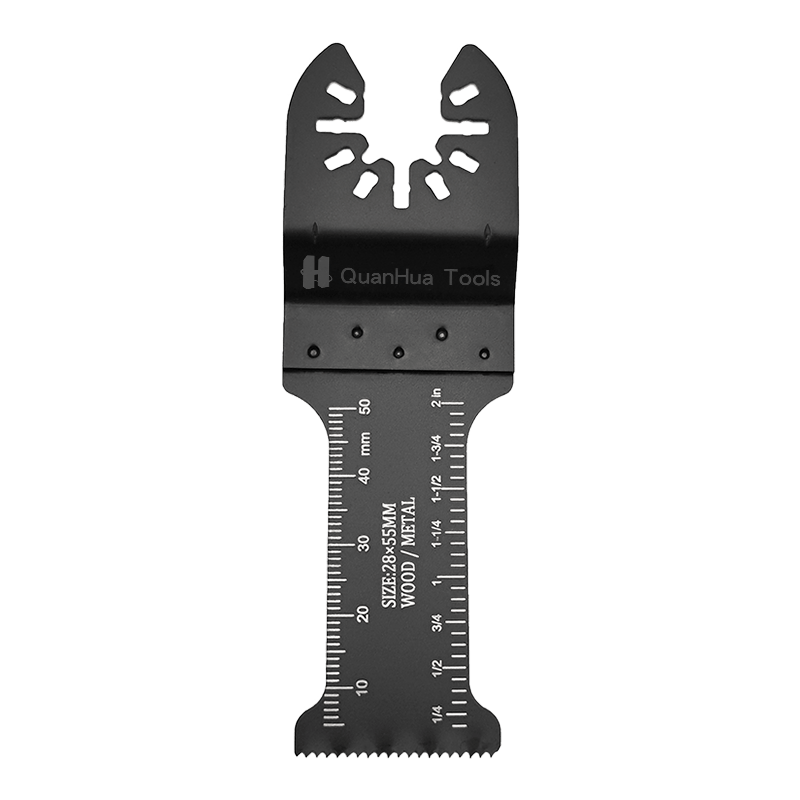

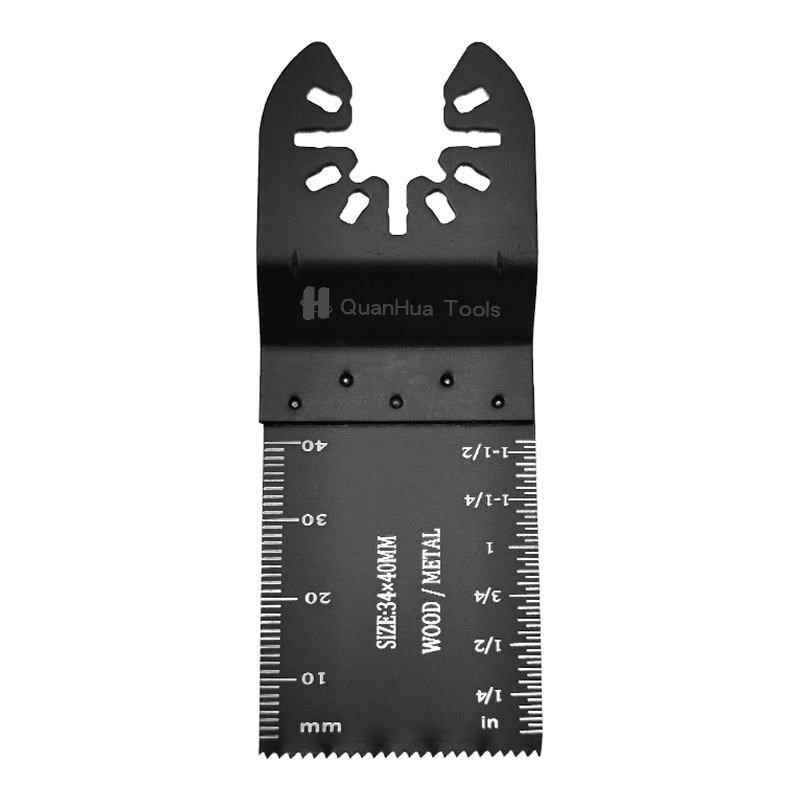

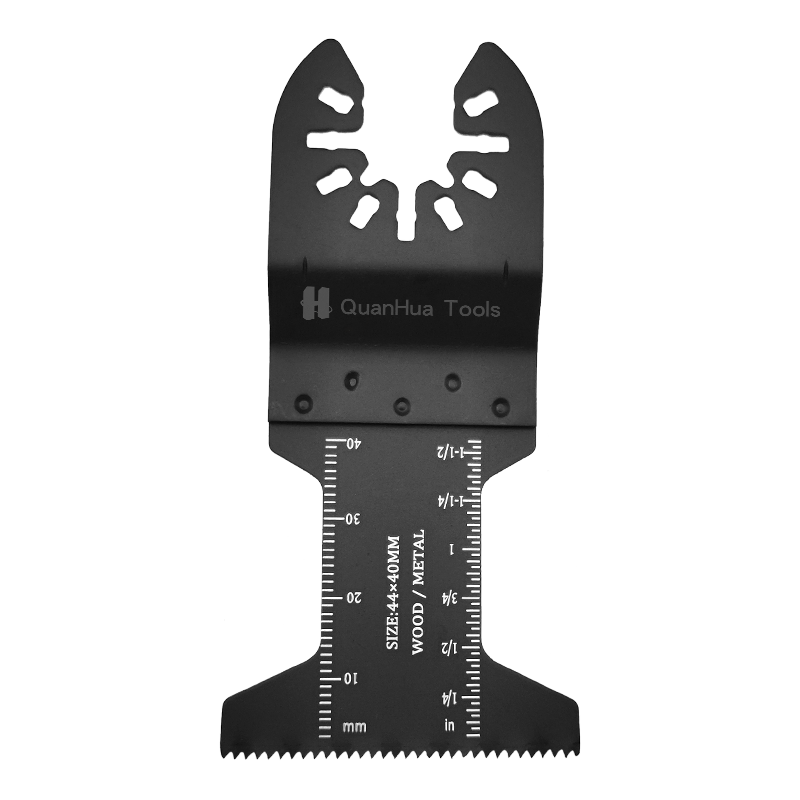

3. Install the saw blade

After the adapter is installed, installing the saw blade is the next critical step. The Starlock interface is designed to simplify the installation process of the saw blade. The user only needs to align the saw blade with the interface and fix it. First, make sure that the center hole of the saw blade is aligned with the positioning pin of the Starlock interface. Then, gently push the saw blade into the interface until you hear a "click", which usually indicates that the saw blade has been properly locked into the adapter. Many Starlock interface adapters are designed with a locking mechanism to ensure that the saw blade will not move or loosen during operation. After installation, perform a simple check to ensure that the saw blade is installed in the correct position and turn the saw blade to verify that it is running smoothly. If the saw blade is found to be offset or unbalanced, it needs to be readjusted to ensure the accuracy and safety of the cutting process.

4. Adjustment and Testing

After completing the installation of the adapter and saw blade, adjusting and testing the equipment is an important step to ensure smooth operation. First, check whether the saw blade is stable during operation without abnormal vibration or noise. Vibration may indicate that the saw blade is not installed correctly or is unbalanced, and the saw blade needs to be readjusted or balanced. Second, perform a test cut to verify that the saw blade cuts as expected in actual use. During the test cut, pay attention to the cut quality and check for uneven cuts or other problems. If the cut effect is not good, the saw blade and adapter position may need to be reinstalled or adjusted. Regular inspection and adjustment can ensure long-term stable operation of the equipment, improve work efficiency, and extend the life of the saw blade and adapter.

5. Maintenance and Replacement

Regular maintenance and replacement of Starlock interface adapters and saw blades are key to keeping the equipment in good condition. Regularly check the adapter for wear and ensure that there are no cracks, deformations or other damage. The locking mechanism and fixtures of the adapter need to be kept clean and in good working order to avoid affecting the stability of the saw blade. Saw blades also wear over time, so they need to be checked regularly for sharpness and cutting results. If a saw blade becomes dull, damaged, or cuts unevenly, it should be replaced promptly. When replacing saw blades or adapters, make sure to follow the manufacturer's recommendations to avoid using incompatible parts. Good maintenance habits not only increase the efficiency of your equipment, but also reduce the additional costs caused by equipment failure. With regular maintenance and correct operation, you can extend the life of your equipment and keep it at its best.