1.Blade Guards: HCS oscillating multitool saw blades often come equipped with robust blade guards or shields as a fundamental safety feature. These guards serve as a protective barrier around the sharp cutting edges of the blade, significantly reducing the risk of accidental contact and potential injuries during operation. By effectively covering the exposed portions of the blade, these guards provide an additional layer of safety, especially in situations where the blade is in close proximity to the user's hands or body. Additionally, some blade guards are designed to retract automatically when the blade is in use, offering maximum protection without compromising cutting efficiency. Manufacturers prioritize the design and construction of these guards to ensure they are durable, reliable, and seamlessly integrated into the blade assembly, enhancing overall user safety and confidence.

2.Precision Engineering: HCS oscillating multitool saw blades are meticulously engineered to deliver precise and controlled cutting performance. Precision is paramount in ensuring safe operation, as it minimizes the likelihood of unexpected movements or deviations that could lead to accidents. These blades are crafted with attention to detail, with each tooth precisely positioned and sharpened to optimize cutting efficiency while minimizing the risk of kickback or binding. Additionally, the blade body is carefully designed to maintain stability and rigidity during operation, further enhancing control and reducing the risk of accidents. By prioritizing precision engineering, manufacturers of HCS oscillating multitool saw blades aim to provide users with a safer and more predictable cutting experience, allowing them to work with confidence even in challenging conditions.

3.Anti-Vibration Technology: Vibration is a common issue associated with power tools like oscillating multitool saws, and excessive vibration can not only affect cutting accuracy but also lead to user fatigue and discomfort. To address this concern, many HCS oscillating multitool saw blades are equipped with advanced anti-vibration technology. This technology typically involves the integration of vibration-dampening materials or mechanisms into the blade design, which help to absorb and dissipate vibrations generated during cutting. By reducing the transmission of vibrations from the tool to the user's hands, arms, and body, anti-vibration technology enhances user comfort and stability, allowing for prolonged periods of operation with minimal fatigue. This not only improves the overall cutting experience but also contributes to a safer working environment by reducing the likelihood of accidents caused by loss of control or impaired judgment due to excessive vibration.

4.Clear Operating Instructions: Proper usage and maintenance are essential aspects of ensuring the safe operation of HCS oscillating multitool saw blades. Manufacturers recognize this and provide clear and comprehensive operating instructions with their products. These instructions typically cover a range of topics, including safety guidelines, usage tips, maintenance recommendations, and troubleshooting advice. By familiarizing themselves with these instructions, users can gain a better understanding of the potential risks associated with operating the tool and learn best practices for minimizing those risks. Additionally, clear operating instructions help users identify and address any issues or concerns that may arise during use, ensuring that they can operate the tool safely and effectively in various applications and environments. Manufacturers may also provide additional educational resources such as online tutorials or instructional videos to further support user education and promote safe operating practices.

5.Compatibility Checks: HCS oscillating multitool saw blades are designed to be compatible with specific multitool models, and ensuring compatibility between the blade and the tool is essential for safe and effective operation. Manufacturers conduct rigorous compatibility checks and testing to verify that their blades are compatible with a wide range of multitool brands and models commonly used by professionals and DIY enthusiasts. Compatibility information is typically provided on product packaging or manufacturer websites, allowing users to easily determine whether a particular blade is suitable for use with their multitool. Using an incompatible blade with a multitool can not only compromise cutting performance but also pose safety risks such as blade slippage or detachment during operation. By prioritizing compatibility checks, manufacturers of HCS oscillating multitool saw blades help users make informed decisions and mitigate the risk of accidents or damage caused by using an incompatible blade with their tool.

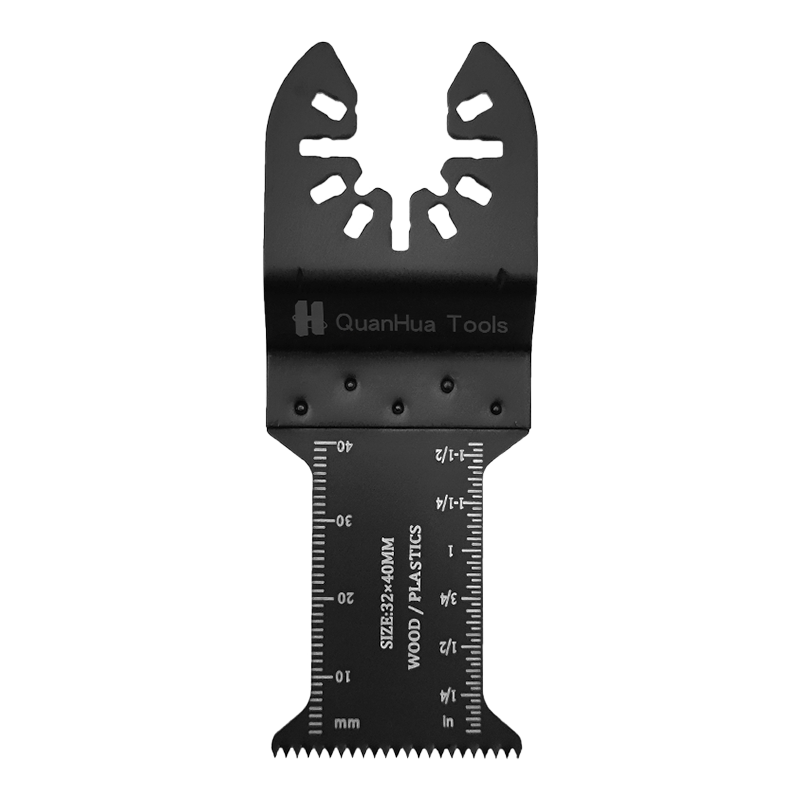

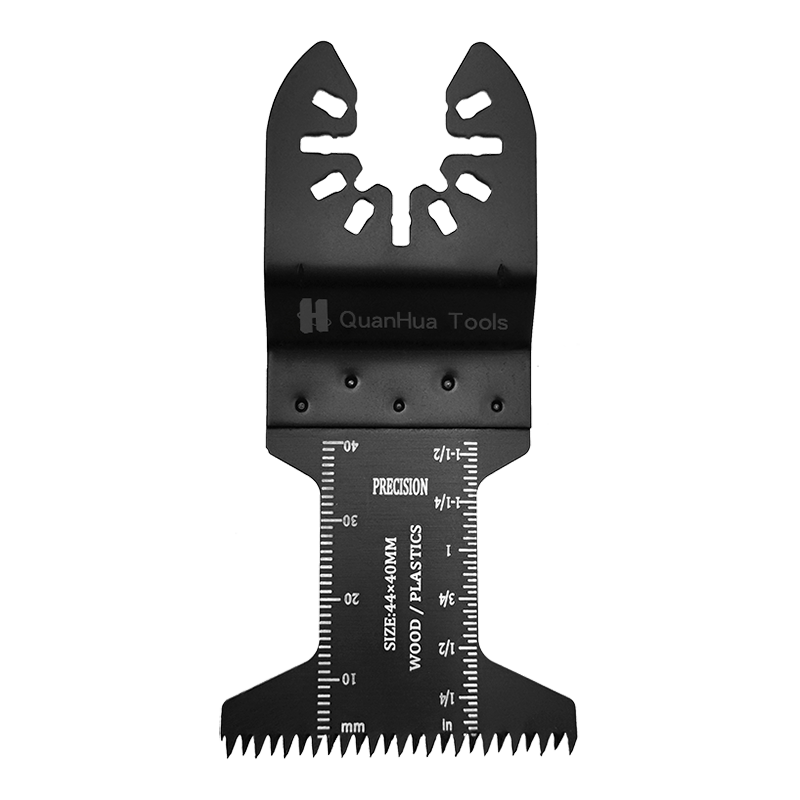

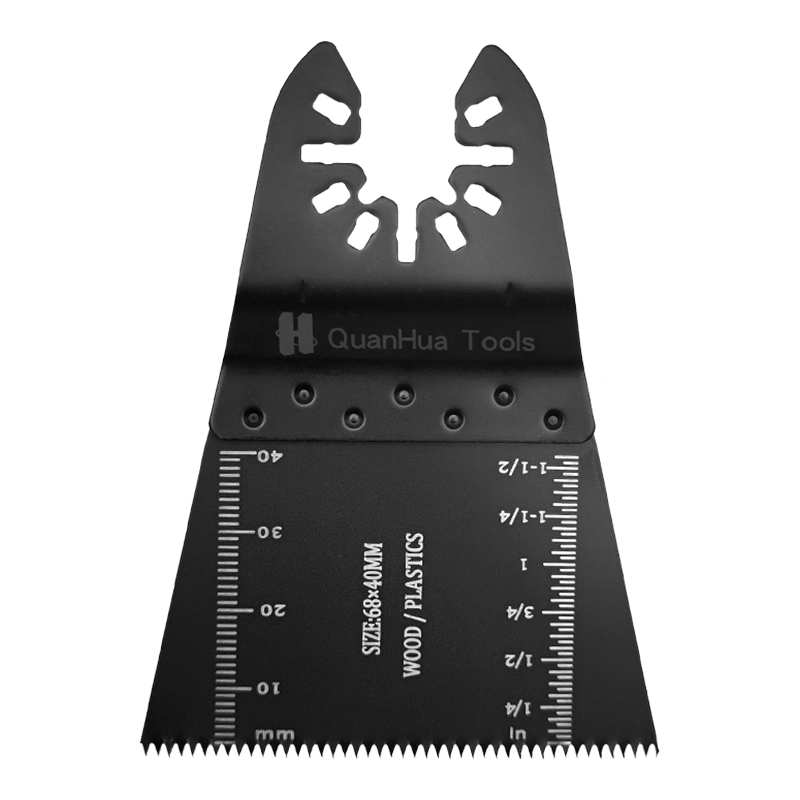

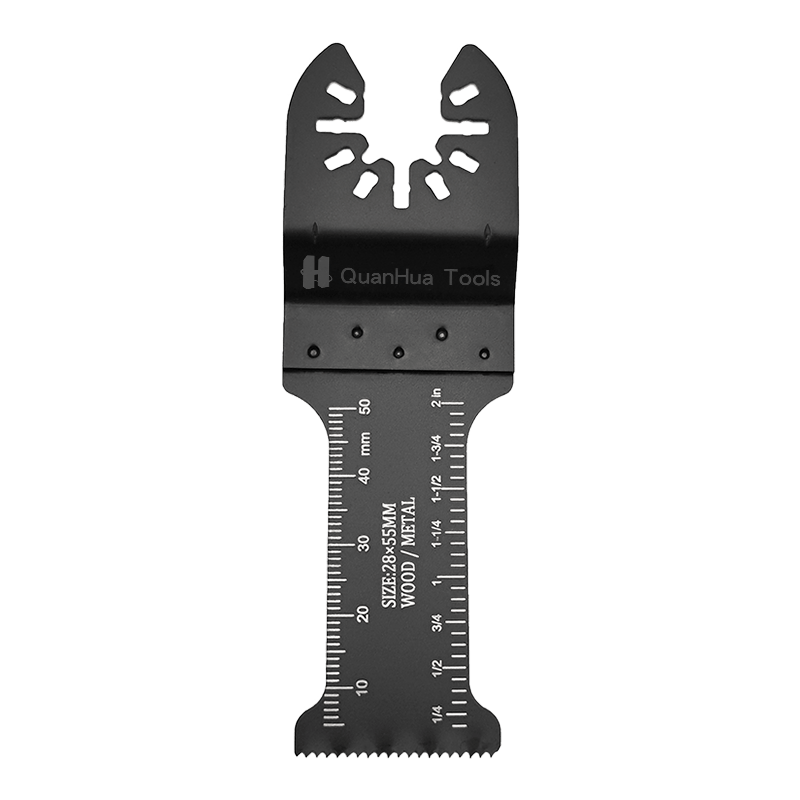

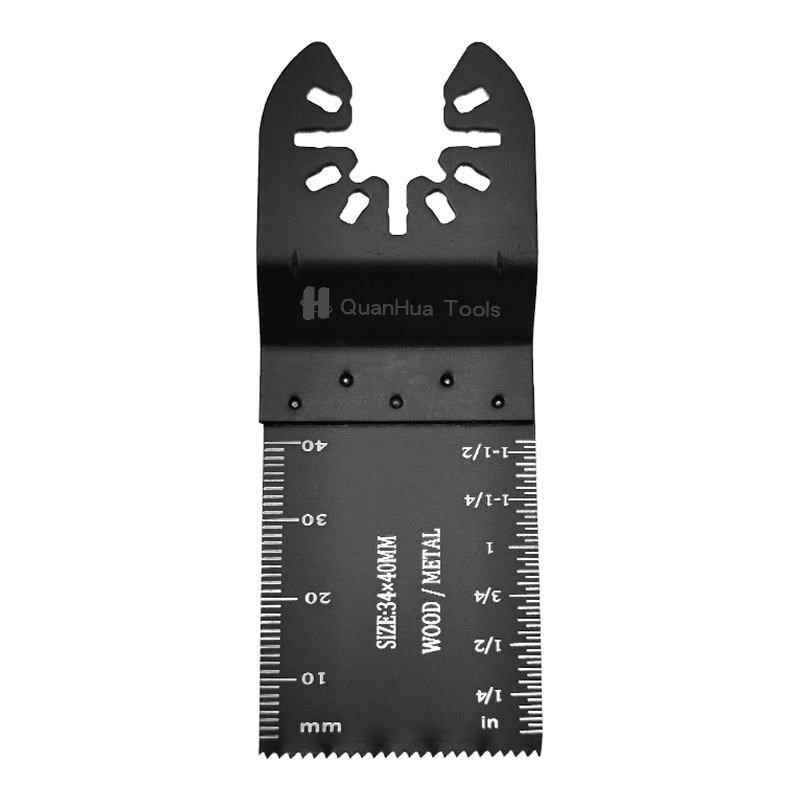

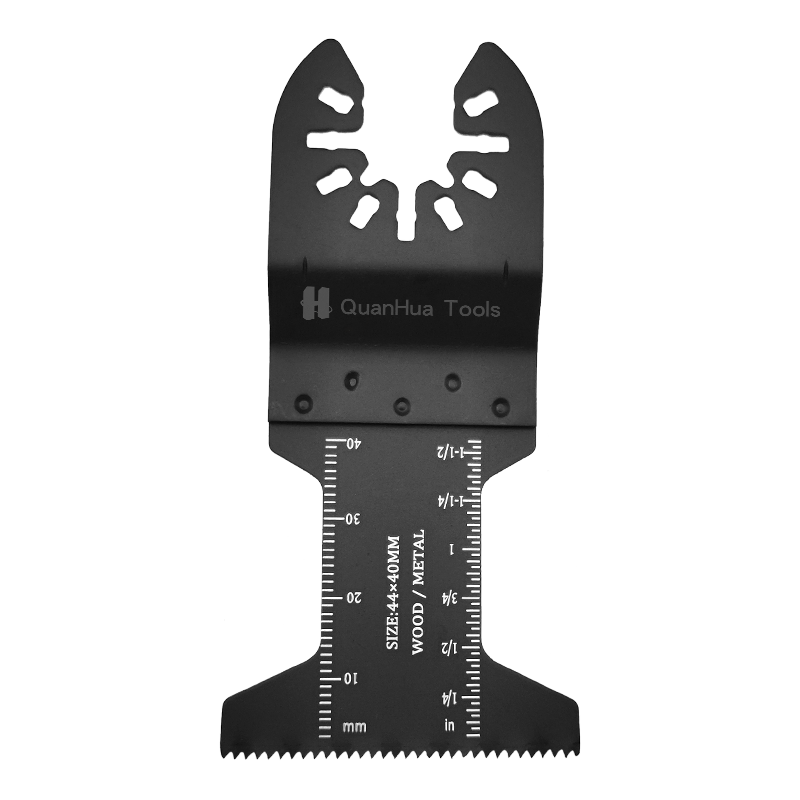

90*68mm Wear-Resistant And Not Easily Broken High Carbon Steel Saw Blades QH-1006K

The 90*68mm Durable High Carbon Steel Oscillating Saw Blade is specifically designed to meet the diverse cutting needs of various materials. Crafted from high-quality high carbon steel, this blade offers exceptional durability, strength, and resistance to wear and breakage. Its unique oscillating design allows for precise and efficient cutting in tight or hard-to-reach areas. It is versatile enough to handle a wide range of cutting tasks, including wood, plastic, fiberglass, nails, non-ferrous metals, and more. The high carbon steel construction ensures clean and smooth cuts without compromising on longevity.