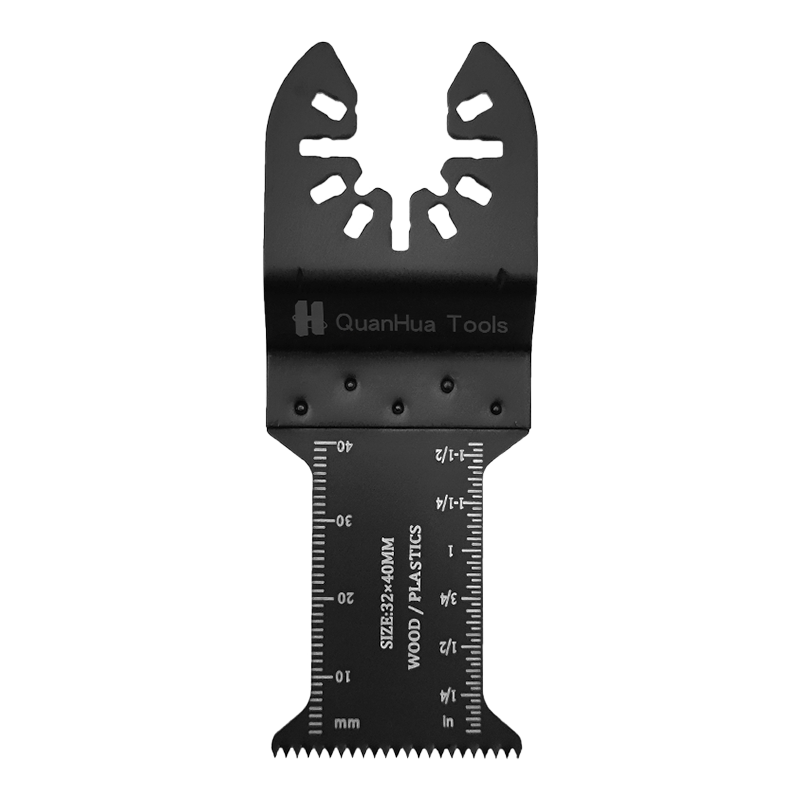

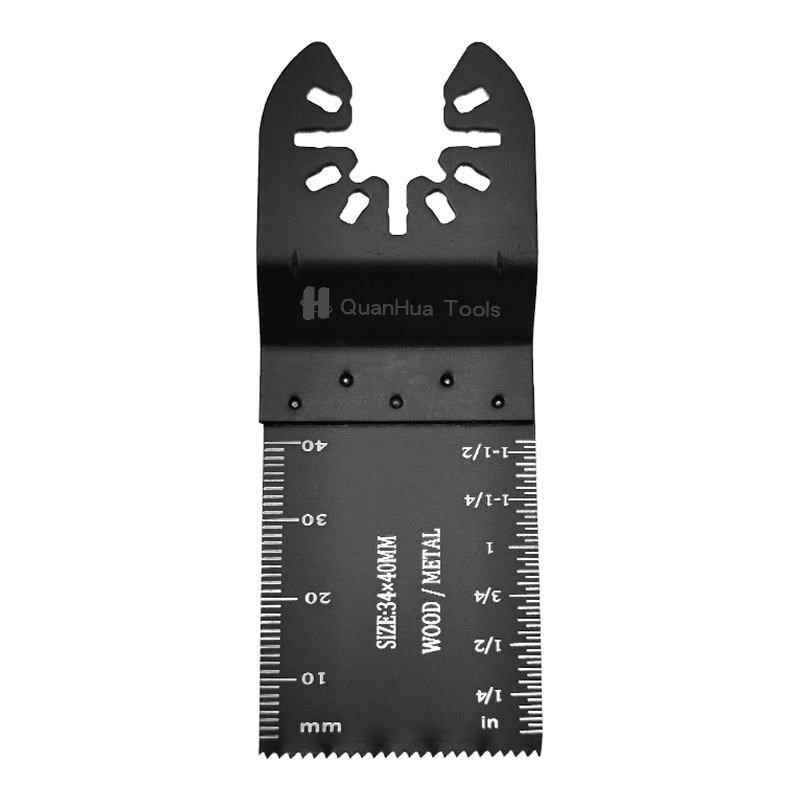

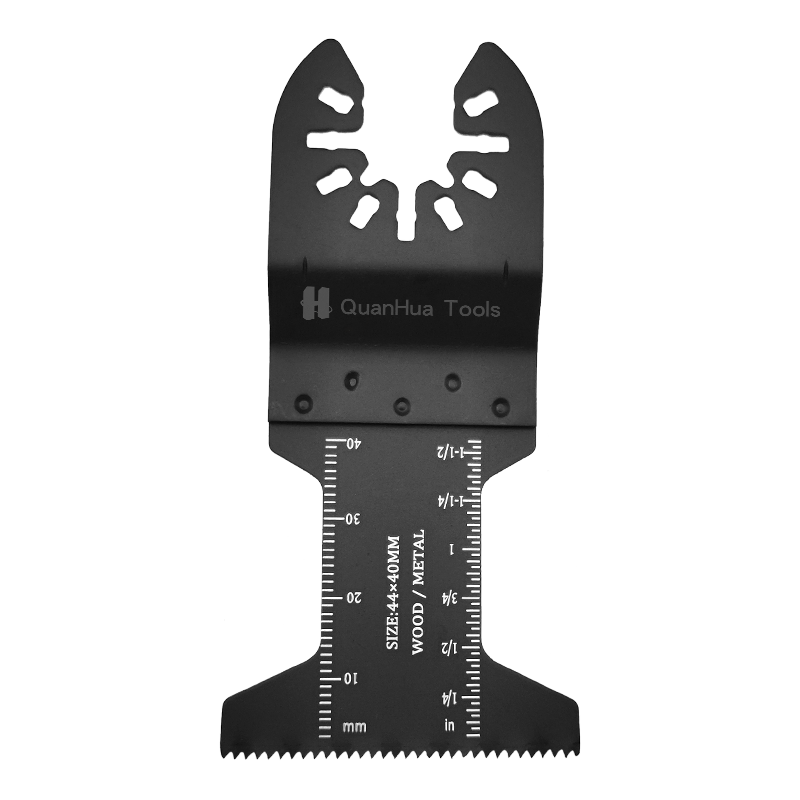

When it comes to the corrugated tooth design of the 32X40MM WAVE TOOTH BIMETALLIC SAW BLADE, one of its advantages is efficient cutting. The corrugated tooth design significantly reduces friction between the saw blade and the workpiece surface through its unique shape and structure. This friction-reducing effect not only makes the cutting process smoother and faster, but also reduces the heat generated by friction in the saw blade, helping to reduce the risk of material deformation during cutting. Especially when working with harder materials, such as steel or alloys, efficient cutting means operators can complete tasks faster and increase productivity.

The corrugated tooth design also provides good chip evacuation. The shape of the corrugated teeth not only helps the chips generated during the cutting process to be discharged from the saw blade more easily, but also effectively reduces the possibility of chips accumulating in the cutting area. This is particularly important for long-term continuous cutting operations, as it reduces the operator's work interruptions caused by frequent saw blade cleaning, thus improving productivity and operational continuity.

The corrugated tooth design also provides enhanced cutting control. The vibration and jitter of the saw blade during the cutting process will affect the cutting quality and accuracy, and the stable design of the corrugated teeth can effectively reduce these vibrations. Operators can more precisely control the cutting path and depth, ensuring that every cut reaches the desired accuracy. This is especially important for industries that require high-precision cutting, such as woodworking, metal processing, etc.

The corrugated tooth design is also very adaptable. Unlike traditional straight tooth designs, corrugated teeth are better able to handle materials of varying hardness and thickness. They distribute cutting pressure more evenly, reducing damage and damage to the material surface, thereby extending the life of the workpiece. Whether working with softwood, hardwood, plastic or metal, corrugated tooth saw blades deliver consistent and efficient cutting performance, making them ideal for a variety of industrial applications and home projects.

The corrugated tooth design can significantly extend the service life of the saw blade. By reducing friction and wear during the cutting process, corrugated tooth saw blades are able to maintain their cutting efficiency and performance over a relatively long period of time. This not only reduces cutting equipment maintenance costs, but also reduces production downtime caused by frequent saw blade changes. Therefore, choosing a 32X40MM corrugated tooth bimetal saw blade can not only improve work efficiency, but also bring about an overall improvement in economic benefits and operational convenience in long-term operation.