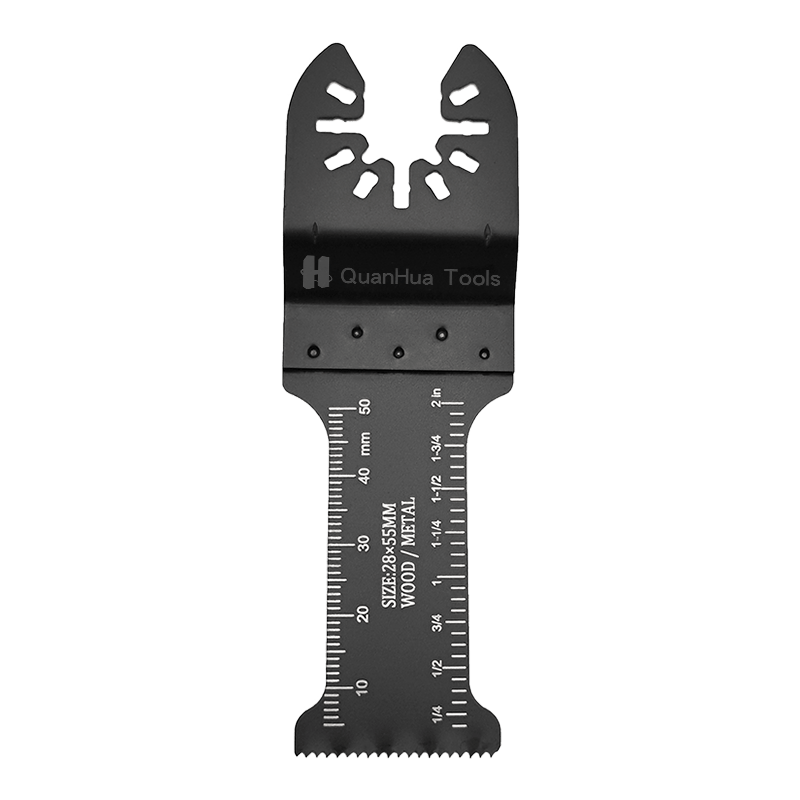

1. Cutting Through Wood and Metal

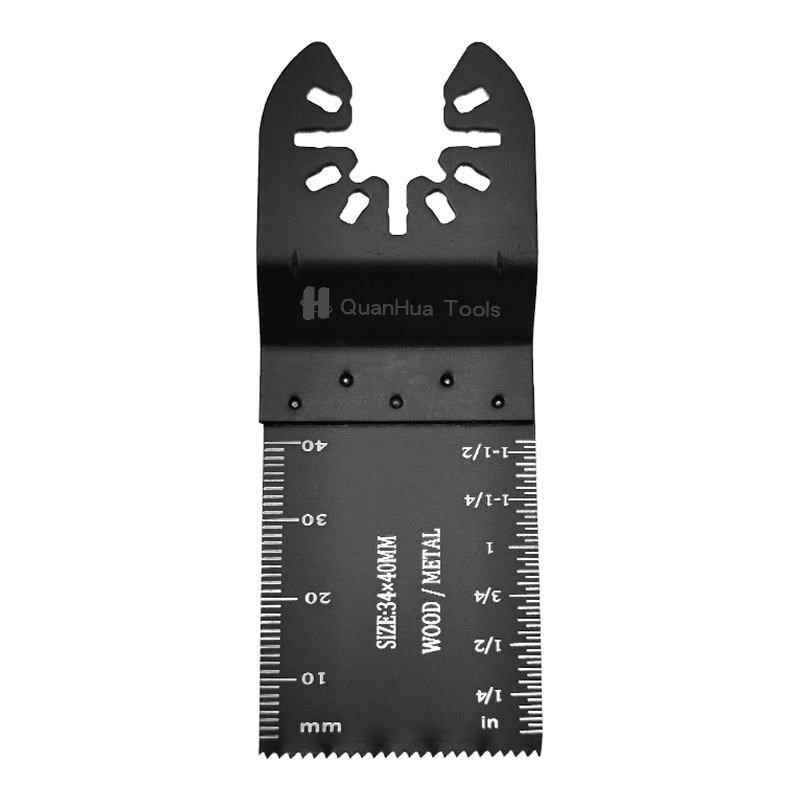

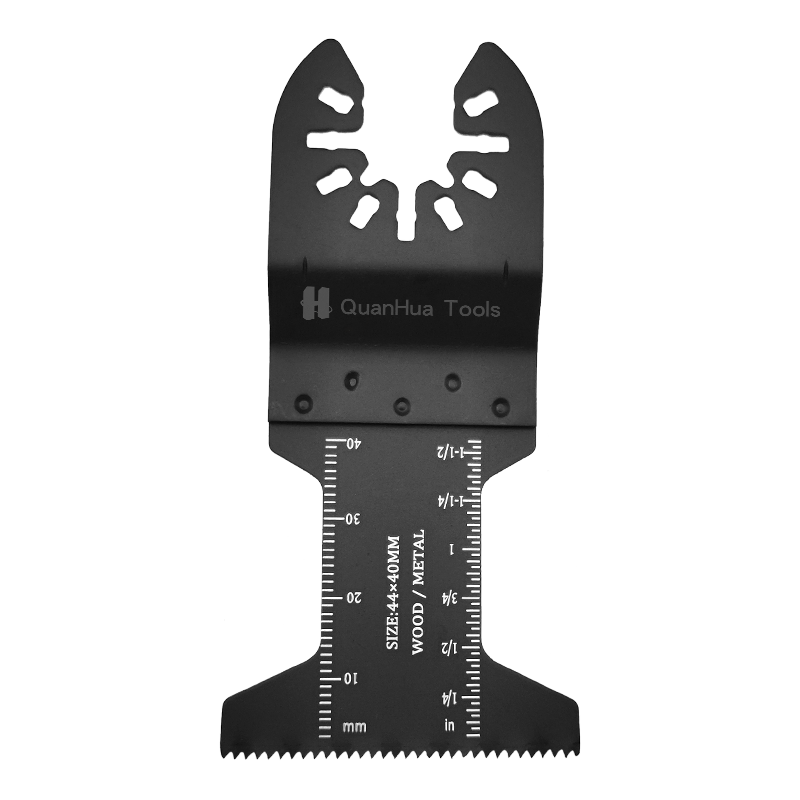

Oscillating alloy saw blades excel in cutting both wood and metal, making them suitable for tasks in carpentry, renovation, and repair. When working with wood, they provide clean and precise cuts through softwoods, hardwoods, and engineered materials like plywood and MDF. This makes them ideal for tasks such as shaping wooden furniture, trimming panels, or creating custom wood designs.

In addition to woodworking, oscillating alloy saw blades are also capable of cutting through soft metals such as aluminum and copper. Their ability to slice through nails, screws, or metal brackets embedded in wood is particularly useful during renovation projects or demolition tasks, where removing old structures often requires cutting through mixed materials. The versatility to handle both wood and metal eliminates the need to switch tools, saving time and effort on the job.

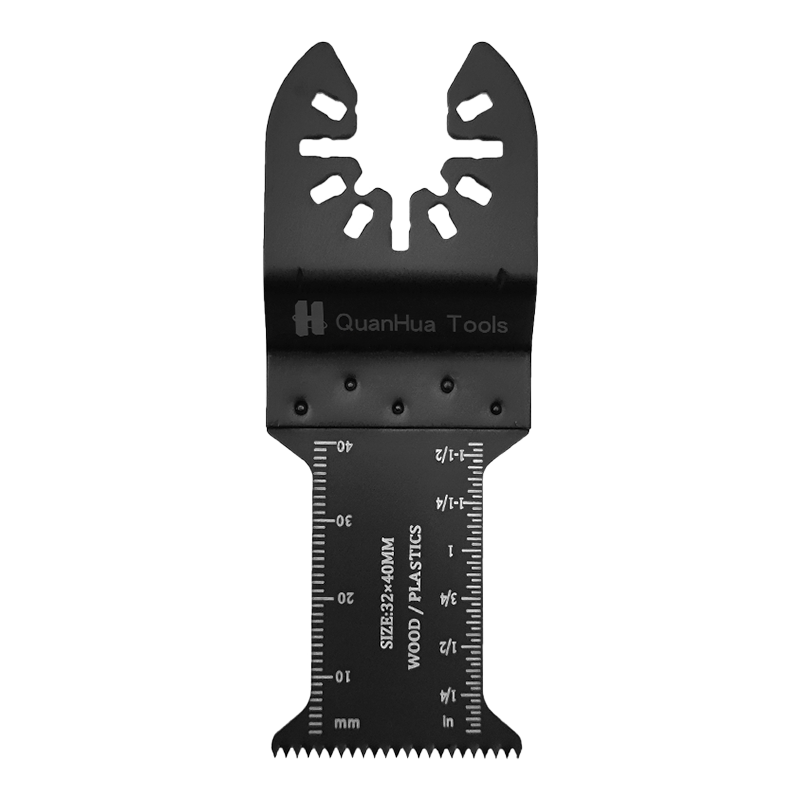

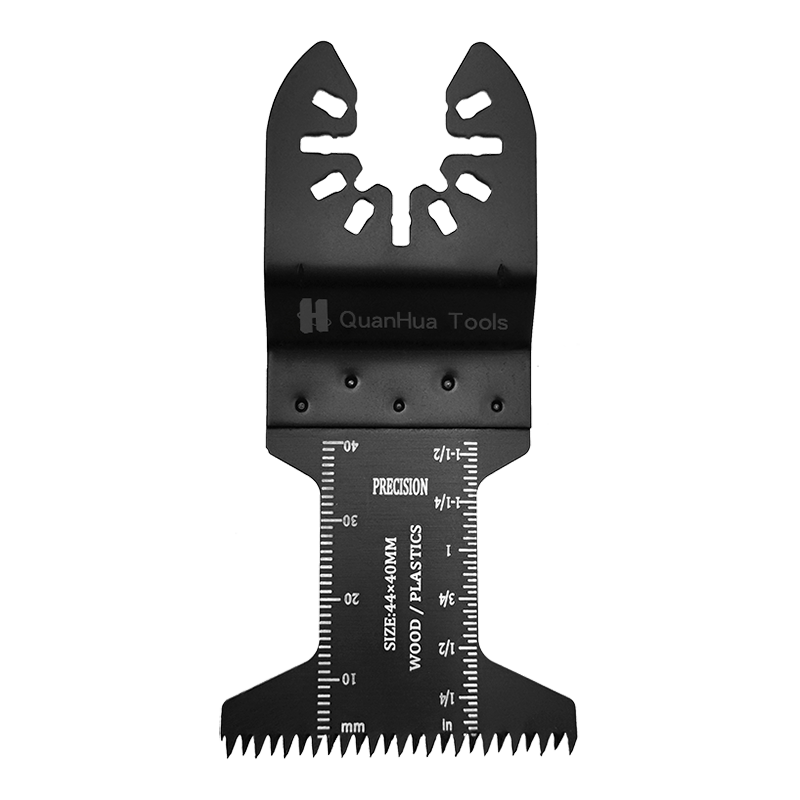

2. Precision Cutting for Tight Spaces

One of the standout features of oscillating alloy saw blades is their ability to make precise cuts in confined or hard-to-reach spaces. Their compact size and oscillating motion allow users to maneuver the blade with ease, making them ideal for intricate tasks that require accuracy.

For instance, when installing flooring, these blades are perfect for trimming baseboards or door frames to ensure a snug fit. Similarly, during cabinetry or furniture assembly, they can be used to make detailed adjustments without damaging surrounding surfaces. Their precision is also invaluable in artistic or decorative projects, where small, delicate cuts are necessary to achieve the desired design. This ability to work in tight spaces with minimal error makes them a go-to tool for professionals and hobbyists alike.

3. Removing Grout and Tiles

Oscillating alloy saw blades equipped with carbide or diamond grit edges are particularly effective for removing grout between tiles. This task is common in bathroom and kitchen renovations, where outdated or damaged grout needs to be replaced. The oscillating motion ensures controlled and accurate removal, preventing damage to surrounding tiles.

In addition to grout removal, these blades can cut through ceramic tiles or natural stone with the appropriate attachment. This makes them valuable for resizing tiles or creating custom shapes to fit unique layouts. The precision of oscillating blades reduces the risk of cracks or chips, ensuring a professional finish. Their efficiency in handling grout and tile work saves both time and effort, making them a favorite tool for contractors and remodelers.

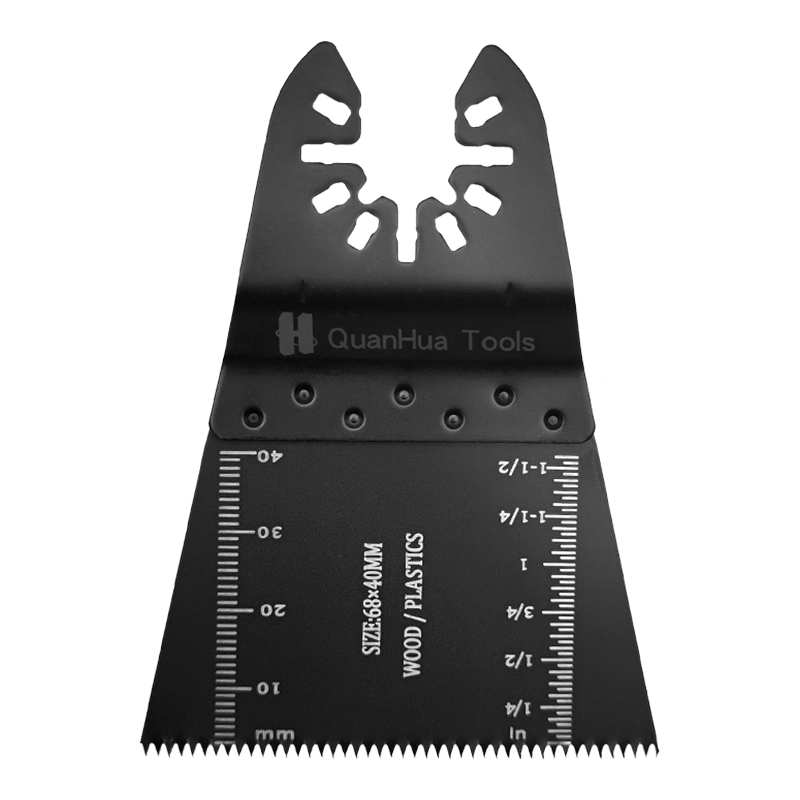

4. Demolition and Remodeling Projects

Oscillating alloy saw blades are built to withstand the rigors of demolition and remodeling projects. They can easily cut through drywall, wooden studs, and pipes, making them essential for tasks such as creating openings for electrical wiring or plumbing installations.

During remodeling, these blades are used to remove old fixtures, trim excess material, or adjust existing structures. For instance, cutting through old drywall to install new outlets or resizing wooden frames to fit new designs is made simple with these tools. The ability to switch between cutting wood, metal, and composite materials without changing tools enhances their practicality. Their durability and versatility make them an invaluable asset on construction sites, where efficiency and adaptability are paramount.

5. Automotive and Plumbing Repairs

In automotive and plumbing repairs, oscillating alloy saw blades are prized for their precision and adaptability. For automotive tasks, they are used to cut through rusted bolts, exhaust pipes, or plastic panels. Their compact design allows them to reach tight areas under the hood or beneath the vehicle, where other tools might struggle.

In plumbing, these blades can cut through PVC pipes, copper tubing, or metal fittings with ease. Whether it's replacing a damaged section of pipe or installing a new fixture, the precision of oscillating blades ensures clean cuts that facilitate a secure fit. Their versatility extends to cutting seals or gaskets without damaging adjacent components. This makes them an indispensable tool for plumbers and mechanics who value precision and reliability in their work.