1. Material selection:

The wear resistance of the Oscillating Saw Blade depends first on the material selected. High carbon steel plays an important role in blade manufacturing due to its high hardness and wear resistance. However, pure hardness is not enough to cope with all cutting needs, so bimetal structures have become a trend. This structure combines the characteristics of different metal materials, such as the combination of high-speed steel and carbon steel, so that the blade has a certain degree of toughness and wear resistance while maintaining sufficient hardness. This trade-off in material selection results in a significant improvement in wear resistance and service life of the Oscillating Saw Blade.

2. Heat treatment process:

The heat treatment process is critical to the wear resistance of Oscillating Saw Blade. Heat treatment steps such as quenching and tempering can not only adjust the hardness and toughness of the blade, but also improve its internal structure and wear resistance. In particular, the treatment of carbides has a decisive impact on the wear resistance of high-speed steel cutting tools. By optimizing the formation and change patterns of carbides, the blade can be reduced in brittleness while maintaining high hardness, thereby significantly improving its wear resistance and service life.

3. Coating technology:

Coating technology is another important means to improve the wear resistance of Oscillating Saw Blade. As an advanced coating technology, titanium alloy coating can not only effectively reduce the friction between the blade and the workpiece, reduce the wear rate, but also increase the hardness and toughness of the blade. The application of this coating technology has made the Oscillating Saw Blade a qualitative leap in wear resistance and service life. At the same time, with the continuous development of coating technology, more advanced coating materials and technologies will be used in the manufacturing of Oscillating Saw Blade in the future.

4.Tooth design:

Tooth design also has an important impact on the wear resistance of Oscillating Saw Blade. Reasonable tooth design can reduce blade wear during cutting and increase service life. Optimization of tooth profile parameters such as tooth pitch, tooth height, and tooth angle can make the blade smoother during the cutting process, reduce resistance, and thereby reduce the wear rate. In addition, the selection of tooth profile should also take into account the characteristics of the cutting material and cutting needs to achieve the best cutting effect and wear resistance.

5. Operation and maintenance:

Proper operation and maintenance are essential to extend the life of your Oscillating Saw Blade. First of all, avoid using it beyond the blade's applicable range to avoid damage to the blade due to overload. Secondly, it is also very important to keep the blade clean and sharp. Regularly cleaning the impurities and dirt on the blades and promptly replacing severely worn blades can ensure that the blades are always in good working condition. In addition, the blades should be lubricated and maintained regularly to reduce wear and extend service life.

6.Technological progress:

With the continuous advancement of technology, new materials and processes are constantly being used in the manufacturing of Oscillating Saw Blades. For example, using advanced laser cutting and precision grinding technology, blades can be produced that are more precise and wear-resistant. In addition, the application of intelligent and automated technology can also improve the efficiency and life of the blade. For example, automatic replacement and adjustment of blades through intelligent control systems can reduce human operating errors and downtime, and improve production efficiency and blade service life. At the same time, with the continuous development of material science and process technology, more advanced materials and processes will be used in the manufacturing of Oscillating Saw Blade in the future to further improve its wear resistance and service life.

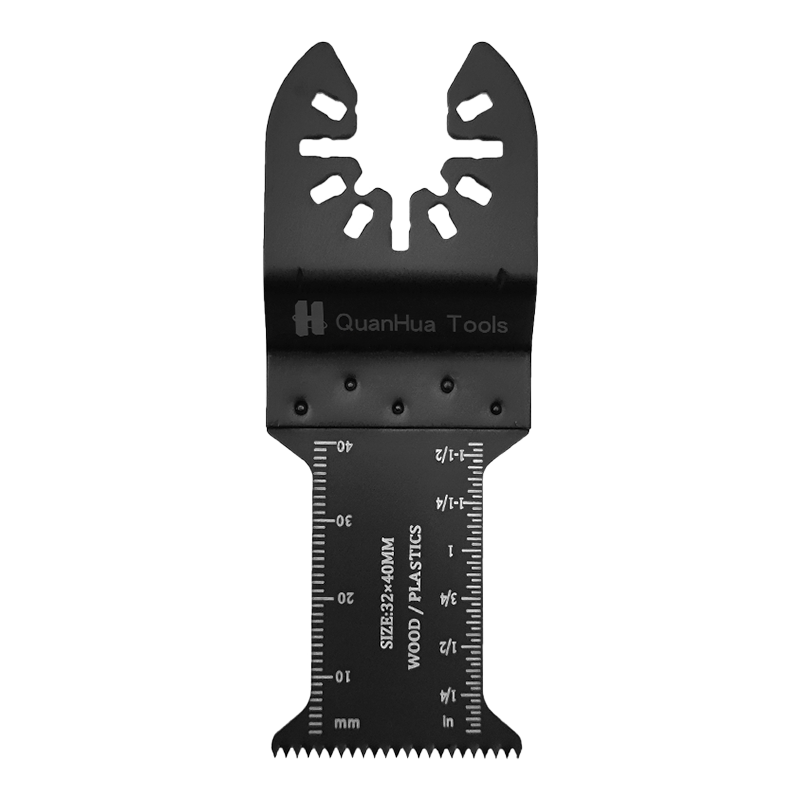

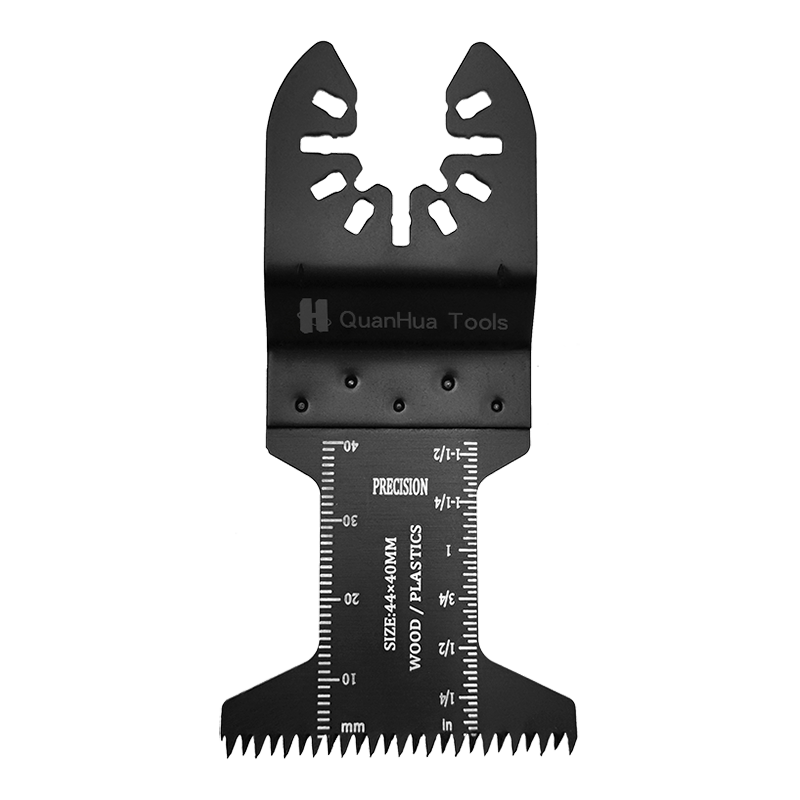

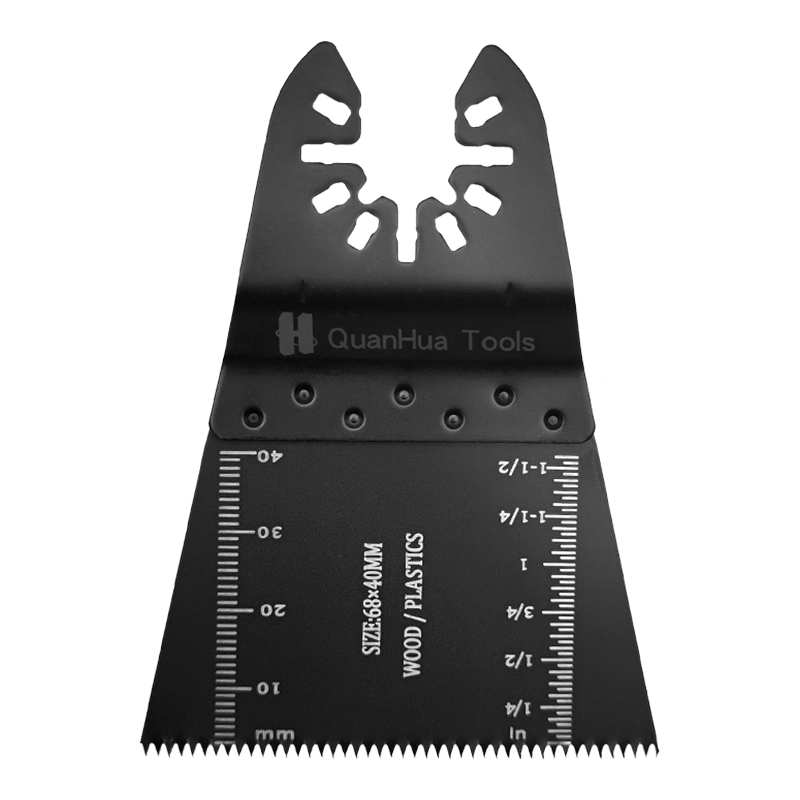

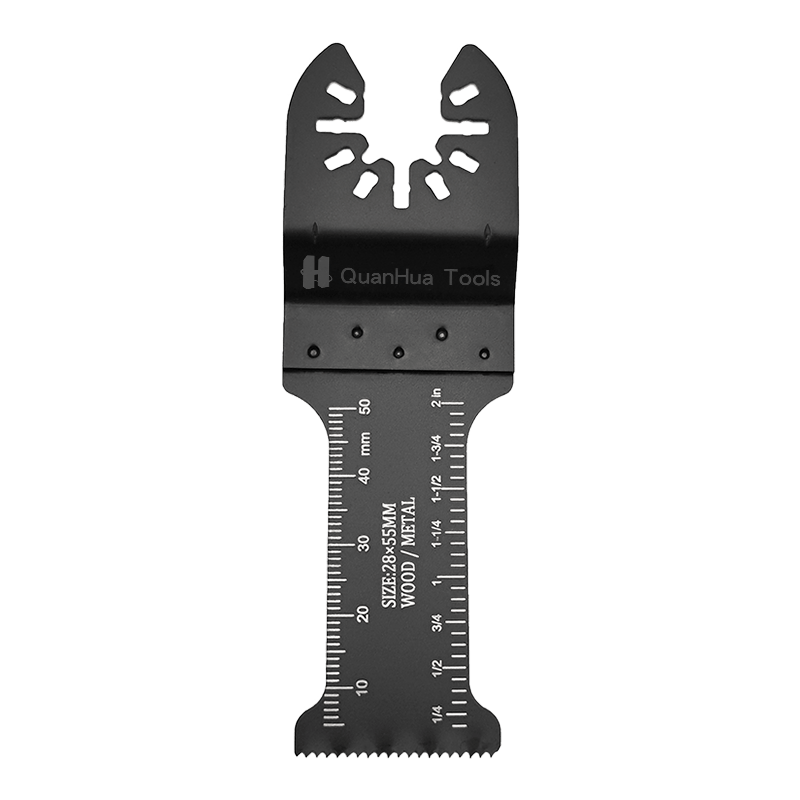

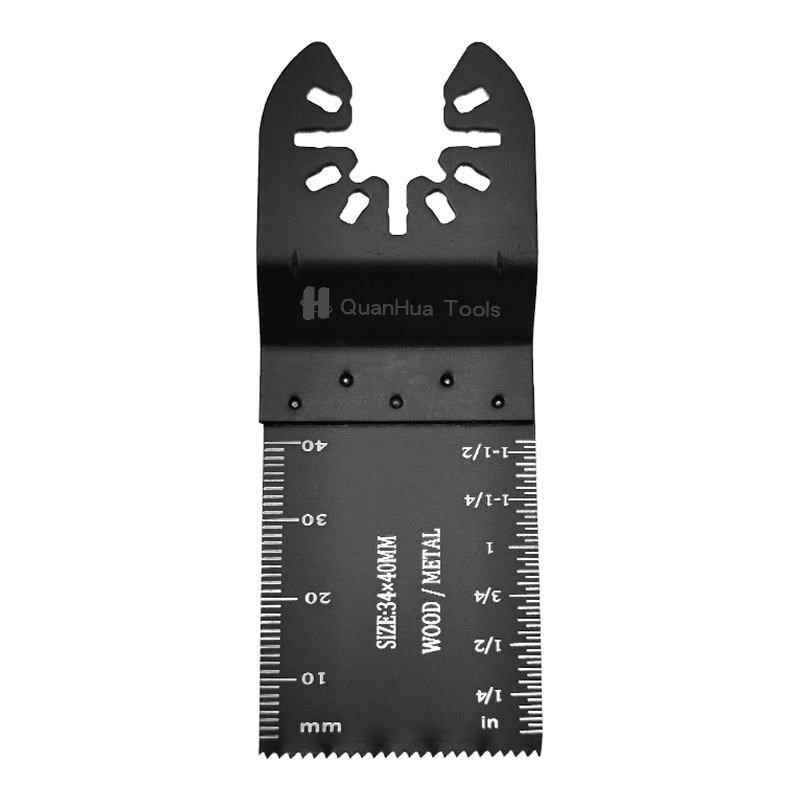

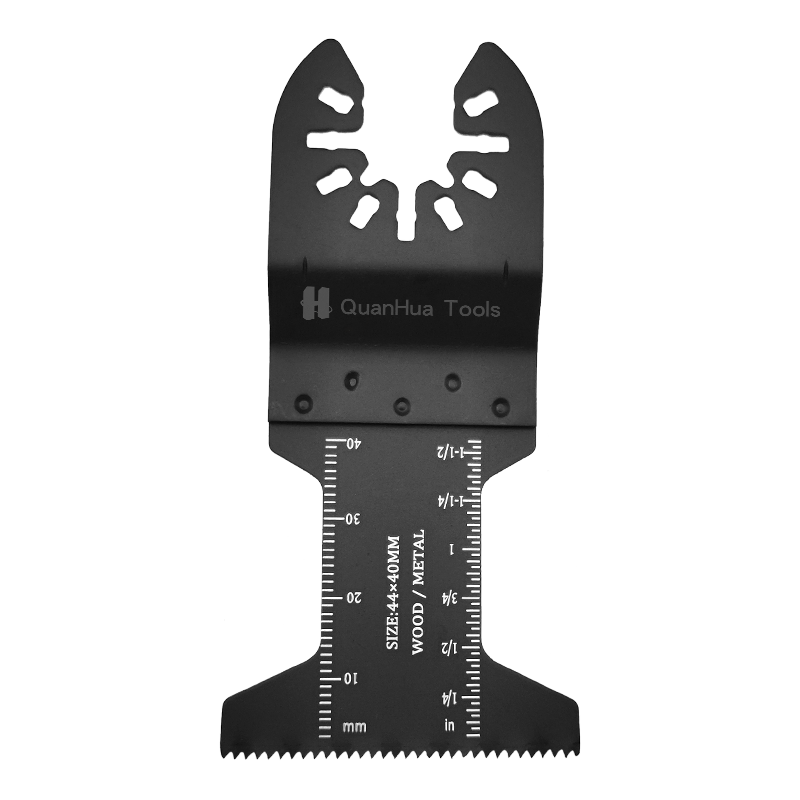

Decoration Wood Cutting High Carbon Steel Saw Blade QH-1003K

The high carbon steel oscillating saw blade is specifically designed for cutting decorative wood during interior decoration. This blade is made from high carbon steel, which ensures its durability and long-lasting performance. The unique oscillating feature of this saw blade allows for precise and smooth cutting, making it an ideal choice for intricate wood designs and patterns. The sharp teeth of the blade provide efficient cutting action, reducing the time and effort required for the task. With its high-quality construction, the high carbon steel oscillating saw blade ensures clean and precise cuts, providing a professional finish to any woodworking project.