Improving the cutting accuracy of TCT (carbide alloy) multi-purpose saw blades is a vital task for many professional users engaged in the processing of metal, wood, plastic and other materials. TCT saw blades are widely used in various fields that require precise cutting due to their strong wear resistance and excellent cutting ability. In order to ensure the best cutting effect, users need to start from multiple aspects, optimize the use method and improve the cutting accuracy.

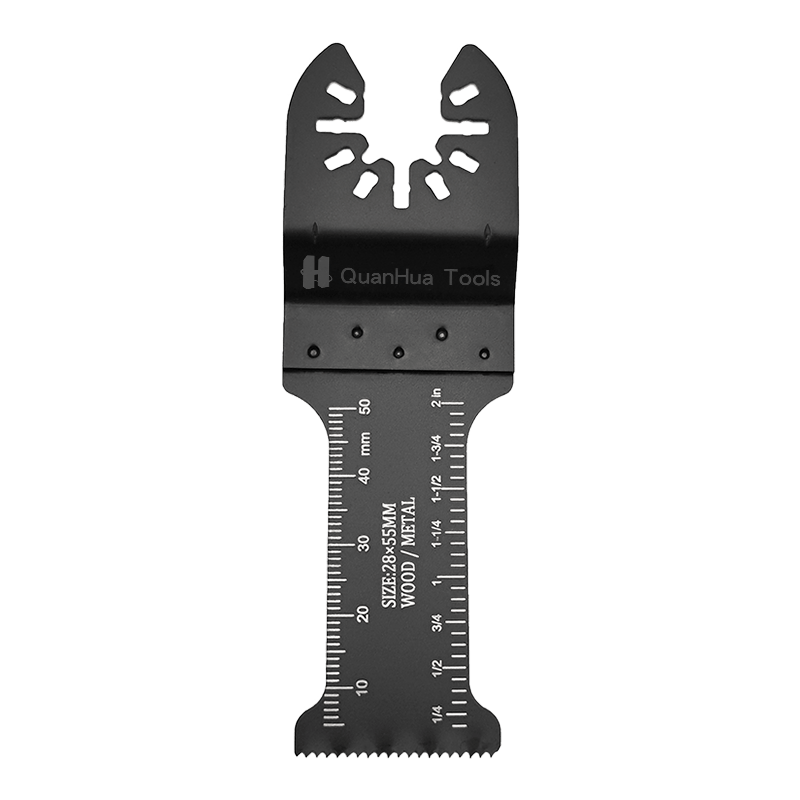

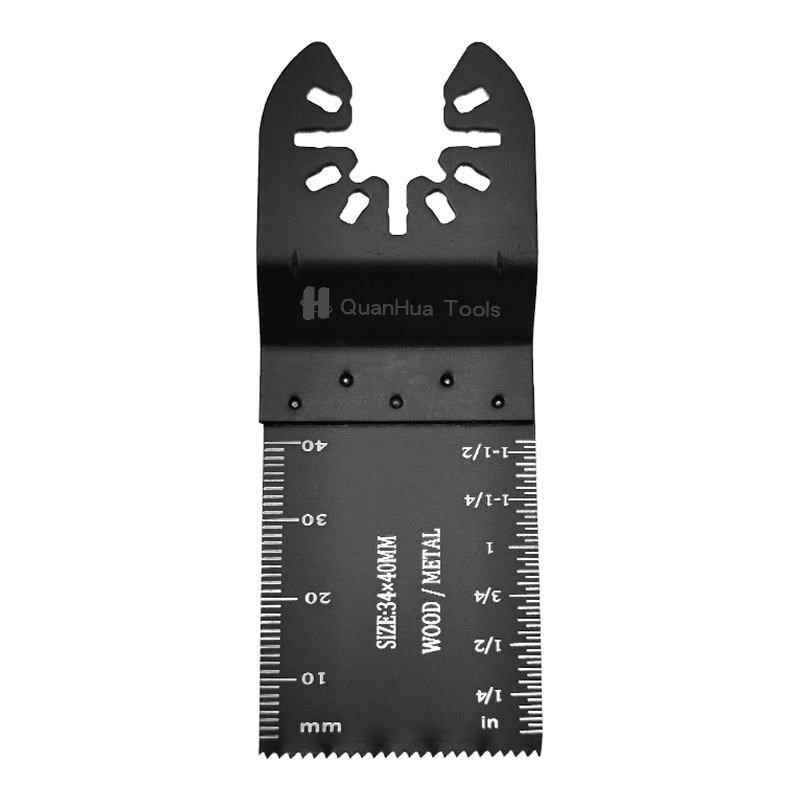

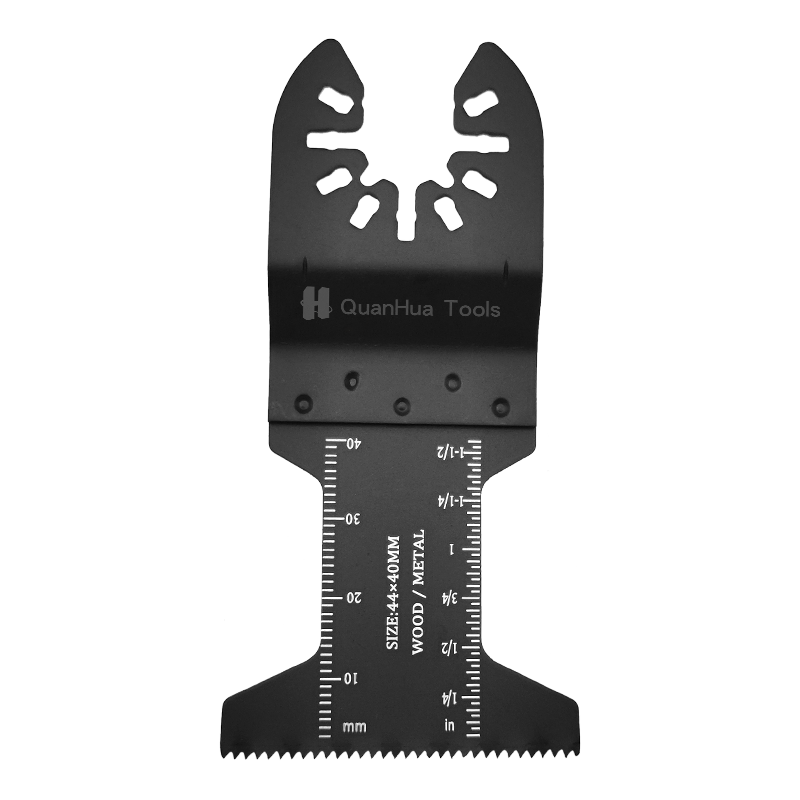

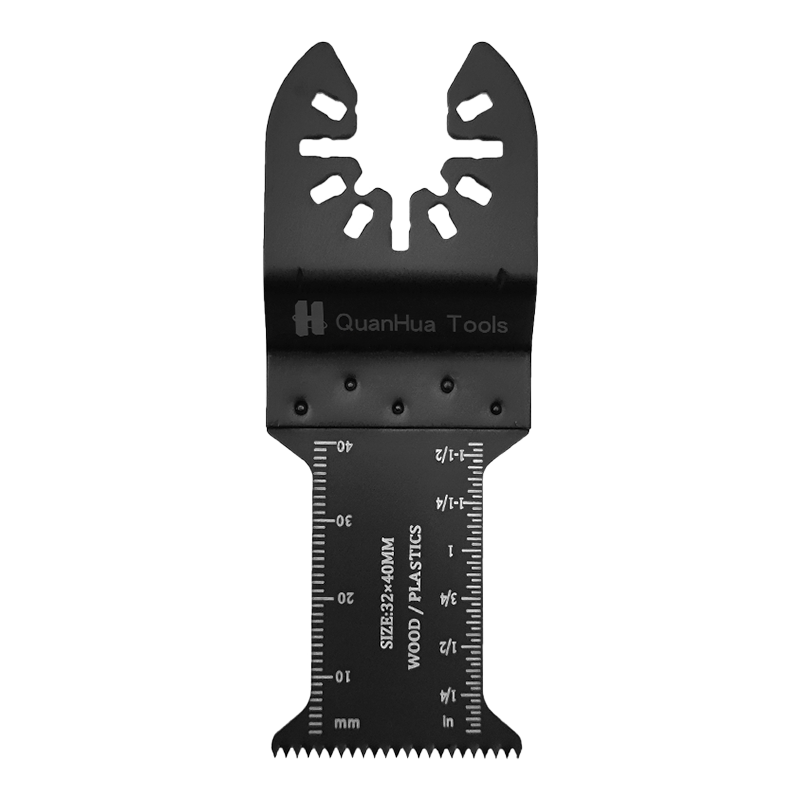

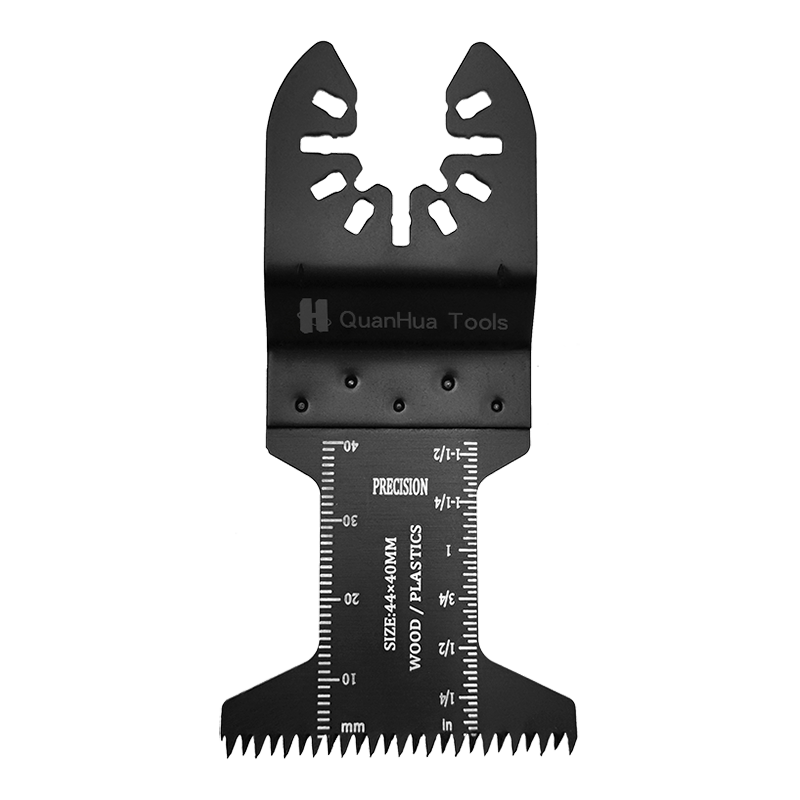

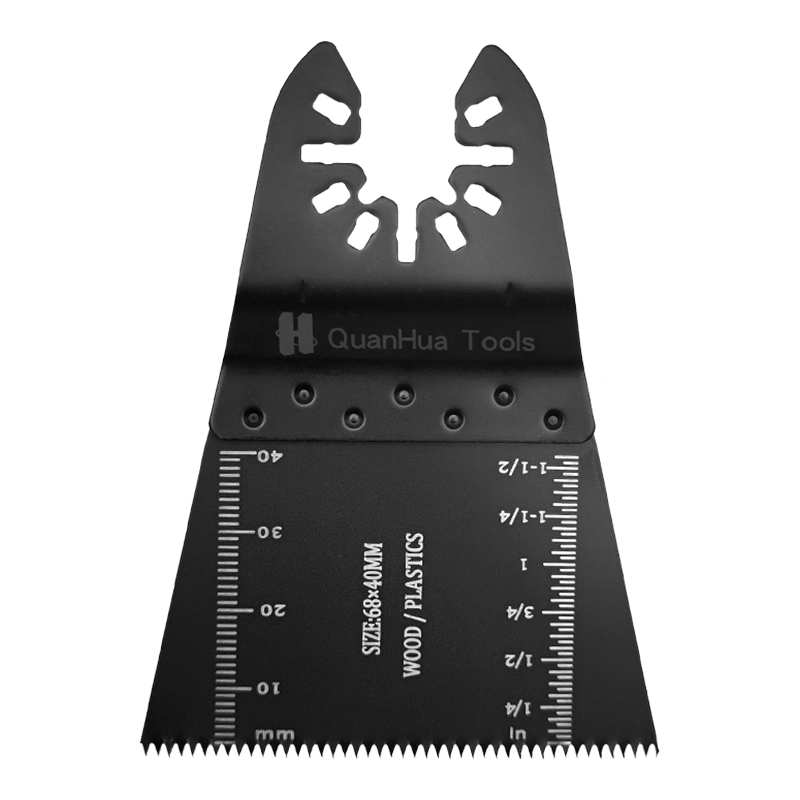

Choosing the right TCT saw blade is the basis for ensuring cutting accuracy. Different types of TCT saw blades have different design characteristics, including tooth shape, number of teeth and cutting angle. The tooth shape and number of teeth directly affect the stability and smoothness of the saw blade when cutting. Generally speaking, saw blades with more teeth can achieve smoother cutting effects because more teeth can share the cutting load, reduce the wear of individual teeth, and thus improve cutting accuracy. When making precision cuts, it is wise to choose saw blades with more teeth. When making rough cuts, choosing saw blades with fewer teeth can help increase cutting speed, although the cutting accuracy may be slightly reduced. The cutting angle is also very critical. The correct angle can not only ensure better cutting results, but also extend the service life of the saw blade and reduce the deflection and unevenness caused by improper cutting angles.

Operation skills play a vital role in improving the cutting accuracy of TCT multi-function saw blades. During the cutting process, it is very important to maintain the correct angle between the saw blade and the workpiece. In general, the saw blade should maintain a certain angle with the surface of the workpiece, which can avoid excessive friction, reduce unnecessary heat accumulation, and help improve cutting accuracy and stability. If the angle is not appropriate during cutting, it is easy to cause uneven cutting surfaces and affect the work effect. The operator should also avoid applying excessive pressure. Excessive pressure will not only cause premature wear of the saw blade, but also make the cutting line unstable, which will eventually affect the cutting quality. The ideal approach is to maintain moderate pressure to ensure that the saw blade can cut smoothly without causing unnecessary stress or deformation to the material. Feed speed is also a key factor affecting cutting accuracy. Feeding speed that is too fast or too slow will affect the cutting effect. Too fast a feed speed will cause the saw blade to not cut effectively, which may cause overheating, jamming or even damage to the saw blade; while too slow a feed speed may cause the cutting process to be too slow, increasing the time the workpiece is in contact with the saw blade, resulting in an uneven cut surface. Finding the right feed speed is an important part of ensuring cutting accuracy.

The quality of tools and equipment also has an important impact on cutting accuracy. Using high-quality, stable tools and equipment can ensure the accuracy of the saw blade during cutting. The performance of vibrating multi-function tools and power tools is crucial to maintaining cutting accuracy. If the tool itself is loose or worn, it may cause the saw blade to vibrate or deflect unstably during operation, which will directly affect the cutting accuracy. Before each use, be sure to check the tightness and working condition of the tool to ensure that the tool is in the best working condition. Using a powerful and stable power tool can ensure that the saw blade has a stable power supply when cutting, which not only improves work efficiency, but also ensures smoothness and accuracy of cutting.

In addition to the tool itself, the maintenance of the saw blade also has an important impact on cutting accuracy. TCT saw blades will wear due to friction after a period of use, resulting in reduced cutting accuracy. Regularly checking the wear of the saw blade and replacing or refinishing it in time is the key to maintaining high-precision cutting. When the tooth tips of the saw blades are worn to a certain extent, their cutting ability will be significantly reduced, the cutting effect will become rough, and even the saw blade will get stuck. To avoid this, the tooth tips of the saw blades should be checked regularly. If they are found to be severely worn, the saw blades should be replaced or repaired immediately to ensure that each cut can achieve the best accuracy.

Fixing the workpiece is also crucial. No matter how good the operating skills are, if the workpiece is unstable, the cutting accuracy will be affected. During the cutting process, the looseness of the workpiece will cause the saw blade to deviate or vibrate, which will affect the cutting effect. In order to ensure cutting accuracy, the workpiece must be firmly fixed on the workbench or fixture to avoid displacement during the cutting process and ensure the stability of the cutting line. It is very necessary to use a suitable fixture or fixture to keep the position of the workpiece, which can effectively avoid inaccurate cutting caused by the movement of the workpiece.