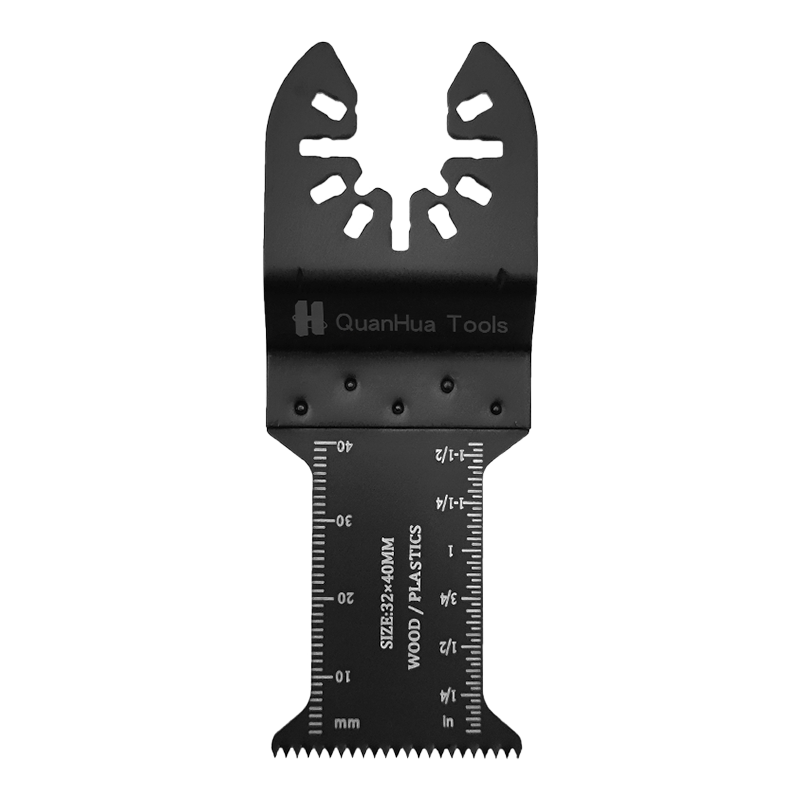

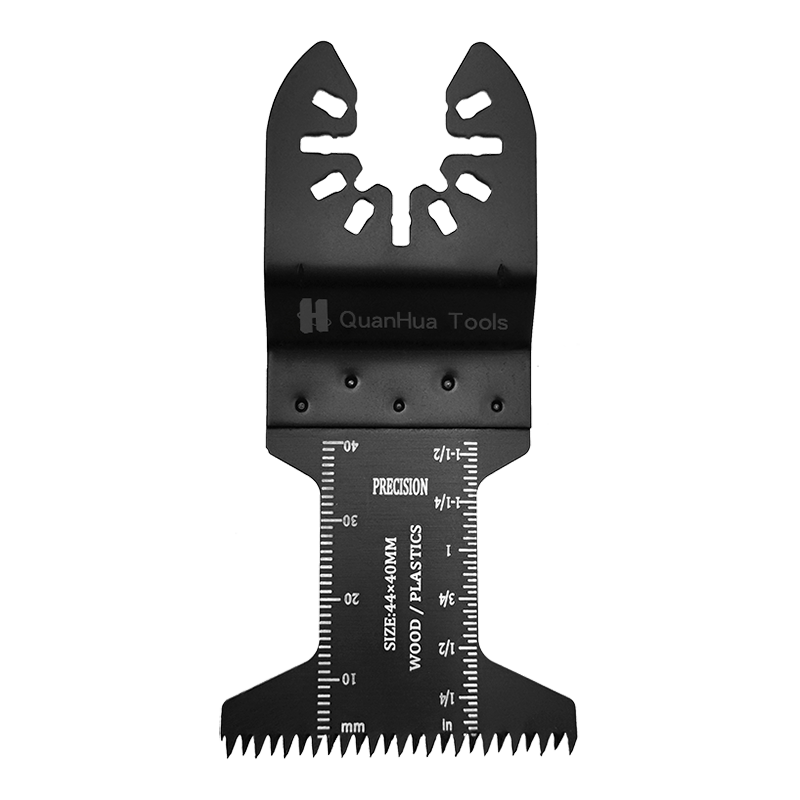

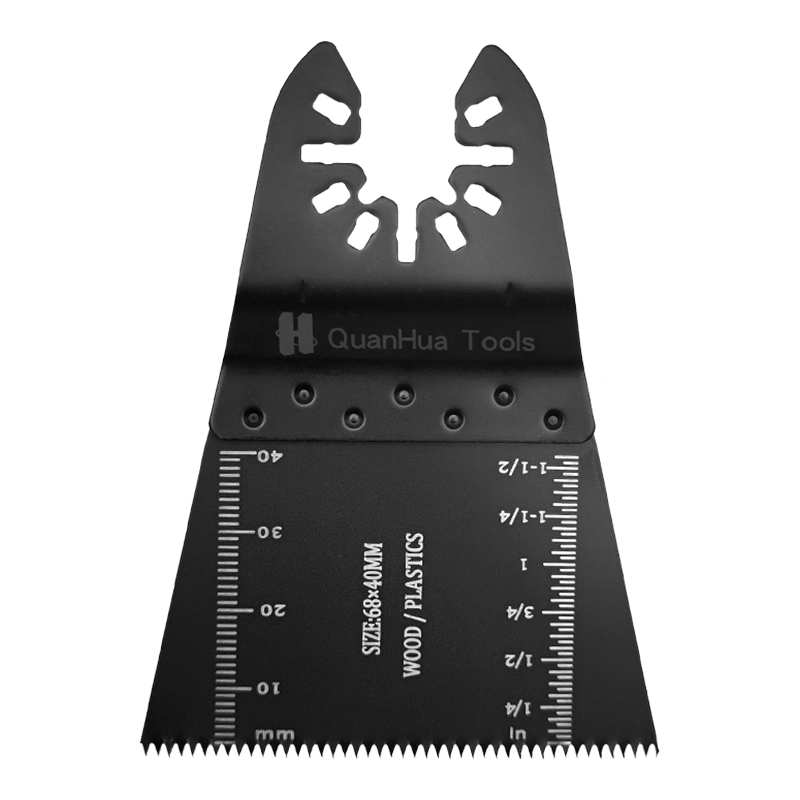

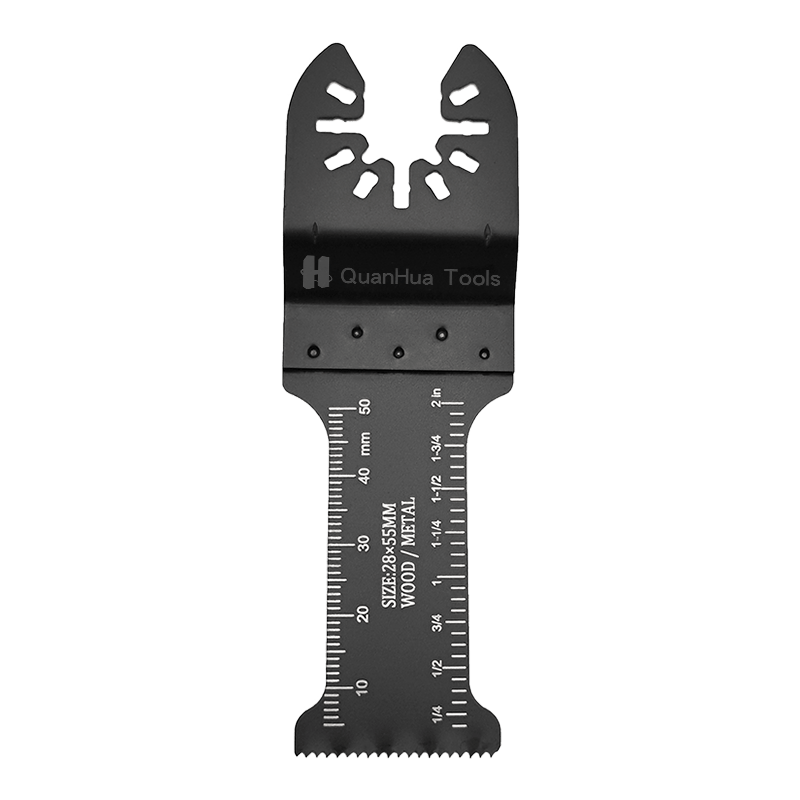

1.Blade design and tooth shape: The blade design and tooth shape of the BIM Oscillating Multitool Saw Blade are critical to cutting speed and efficiency. Excellent blade design ensures stability and precision during cutting, while sharp teeth can quickly penetrate the material, reduce cutting resistance, and increase cutting speed. Some blades also use a corrugated design, which can effectively reduce vibration and noise, making cutting smoother and more efficient.

2.Blade material: BIM Oscillating Multitool Saw Blade is usually made of bimetal (BIM) material, which has excellent wear resistance and toughness, and can maintain the sharpness and stability of the blade during cutting. High-quality BIM blades are usually precision machined and heat-treated to ensure excellent cutting performance and long service life.

3.Working conditions: Cutting speed and efficiency are affected by working conditions. Different types and thicknesses of materials require different cutting methods and working parameters. When cutting harder materials, it may be necessary to adjust the blade speed and cutting angle to give full play to the cutting performance of the blade. In addition, the right lubricant can also improve cutting efficiency and extend the life of the blade.

4.Operating skills:

The operator's skills and experience will also affect the cutting speed and efficiency. Skilled operators can flexibly use multi-functional tools and select the appropriate cutting angle and blade speed to ensure cutting accuracy and efficiency. In addition, correct operating posture and stable hand-holding can also reduce errors and vibrations during cutting and improve work efficiency.

5.Blade wear and maintenance:

Regularly check the degree of blade wear and replace severely worn blades in time to maintain the stability of cutting speed and efficiency. Regular cleaning and maintenance of the blade, such as removing impurities and lubricants accumulated during the cutting process, can also extend the service life of the blade and improve cutting performance.

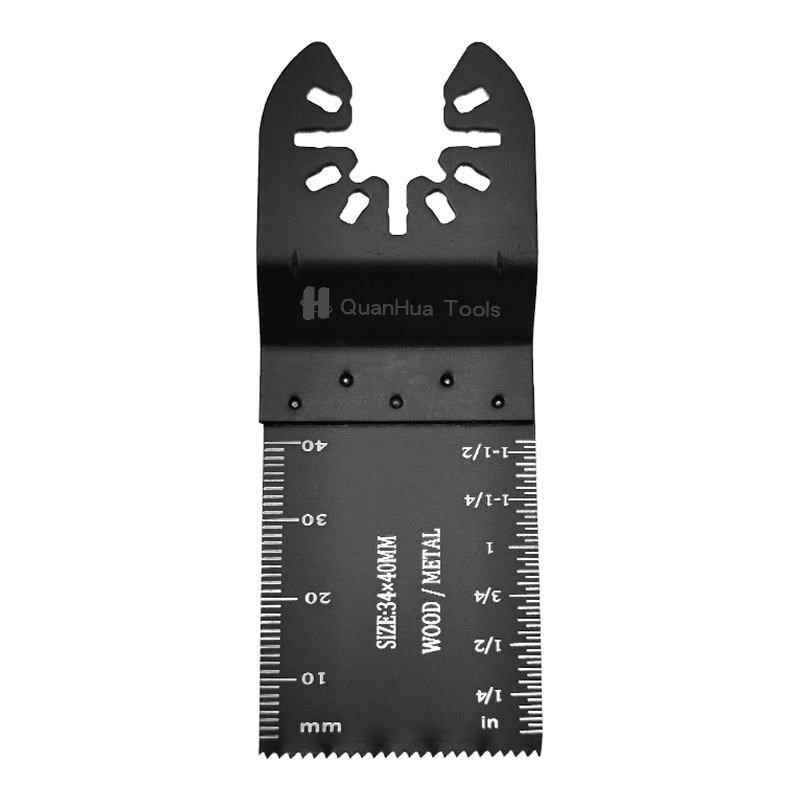

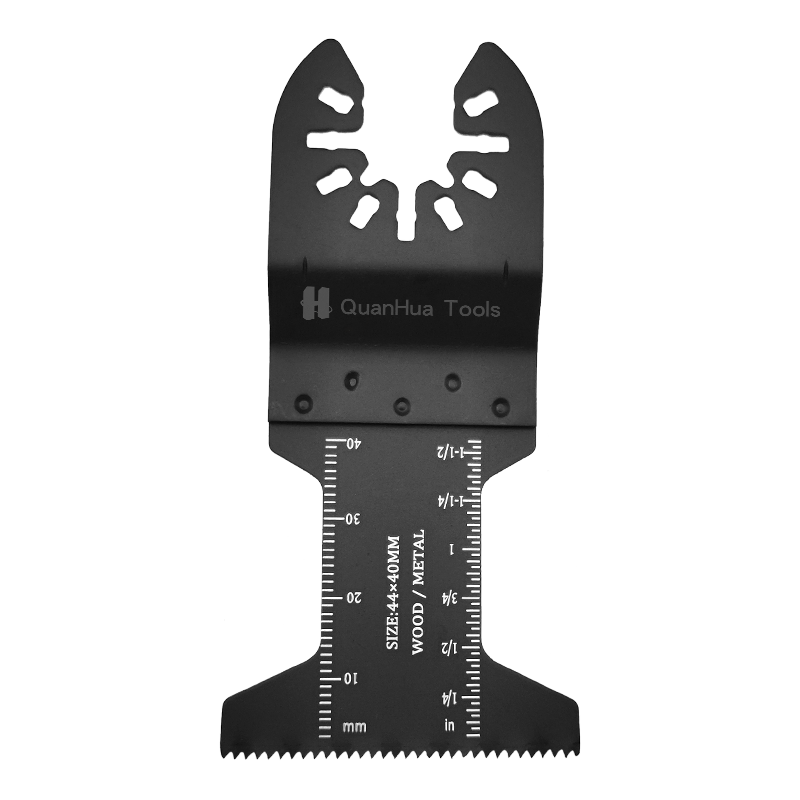

BIMETAL M42 ALUMINUM PLATE CUTTING SAW BLADE QH-1004HK

The oscillating saw blade designed for cutting M42 aluminum plates, also known as dual-metal oscillating saw blades, is a high-performance cutting tool specifically engineered for efficient and precise cutting applications. This blade is specifically designed to handle the unique properties of M42 aluminum, which is a combination of aluminum and cobalt materials. The dual-metal construction of the blade consists of high-speed steel (HSS) teeth along with a flexible steel body. The HSS teeth ensure good cutting performance, while the flexible steel body allows for effortless oscillating movements. This unique blade design provides improved cutting stability and reduced vibrations during the cutting process, resulting in enhanced accuracy and minimized material wastage.