1. Wear resistance of carbide

The carbide material used in Carbide Oscillating Multitool Sabre Saw Blade has extremely high hardness and wear resistance, which lays the foundation for improving cutting efficiency. The advantage of carbide is that it can withstand high-intensity and long-term cutting without becoming blunt or wearing out easily. Traditional steel saw blades may gradually become blunt as the use time increases during the cutting process, which not only affects the cutting speed, but also reduces the cutting accuracy, resulting in reduced production efficiency. In contrast, tungsten carbide saw blades can remain sharp for a longer time, reducing the frequency of saw blade replacement, thereby reducing downtime and ensuring continuous work. Especially when cutting such as metal, ceramics or other hard materials, tungsten carbide saw blades perform particularly well. It can easily cope with these high-hardness materials, reduce cutting delays caused by saw blade wear, and ensure the continuity of the production line. The corrosion resistance and high temperature resistance of tungsten carbide materials also make it perform better in harsh working environments, and can resist the erosion of chemicals and high temperatures, further improving its service life and work efficiency.

2. Multifunctional vibration cutting technology

Multifunctional vibration technology is one of the important features of Carbide Oscillating Multitool Sabre Saw Blade. Compared with traditional rotary cutting, it can reduce material loss while maintaining high cutting efficiency. The principle of vibration cutting is to cut materials through high-frequency reciprocating motion. This motion mode reduces the resistance during cutting and enables the saw blade to maintain high-speed cutting on various materials. Especially when dealing with more complex cutting tasks, such as the need to make precise straight or curved cutting of materials, the flexibility of vibration cutting tools is particularly prominent. Since vibration cutting does not require the saw blade to make a complete rotational motion, it can achieve efficient cutting in a smaller space, which makes it have great advantages in small space operations such as decoration and installation. In addition, vibration cutting can effectively reduce the risk of overheating or deformation of materials, especially when cutting heat-sensitive materials such as plastics and metals, vibration cutting technology can maintain the integrity of the material, thereby reducing the time and cost of secondary processing and improving overall work efficiency.

3. Optimized tooth design

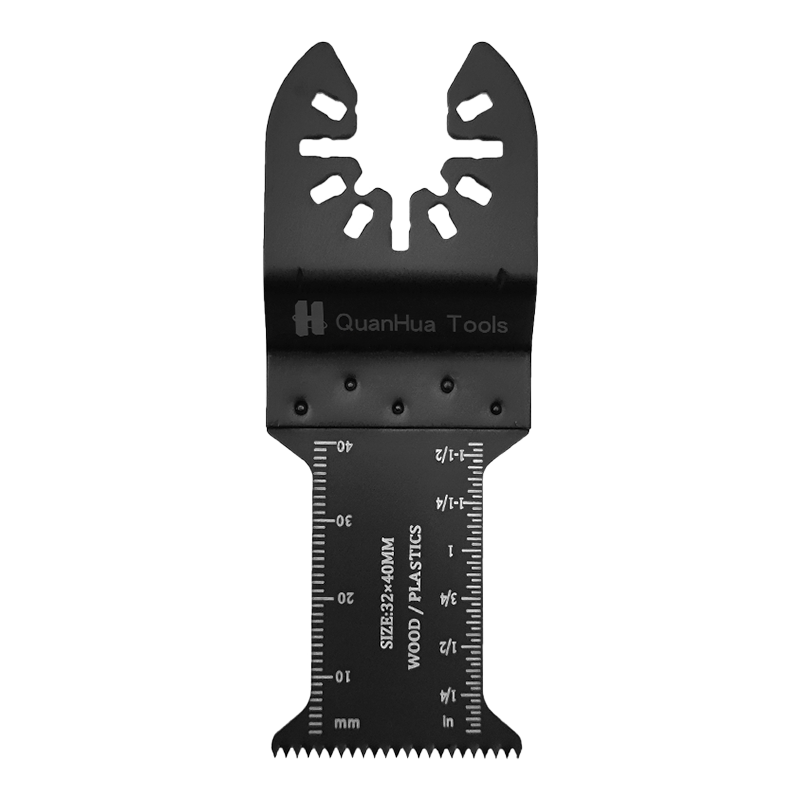

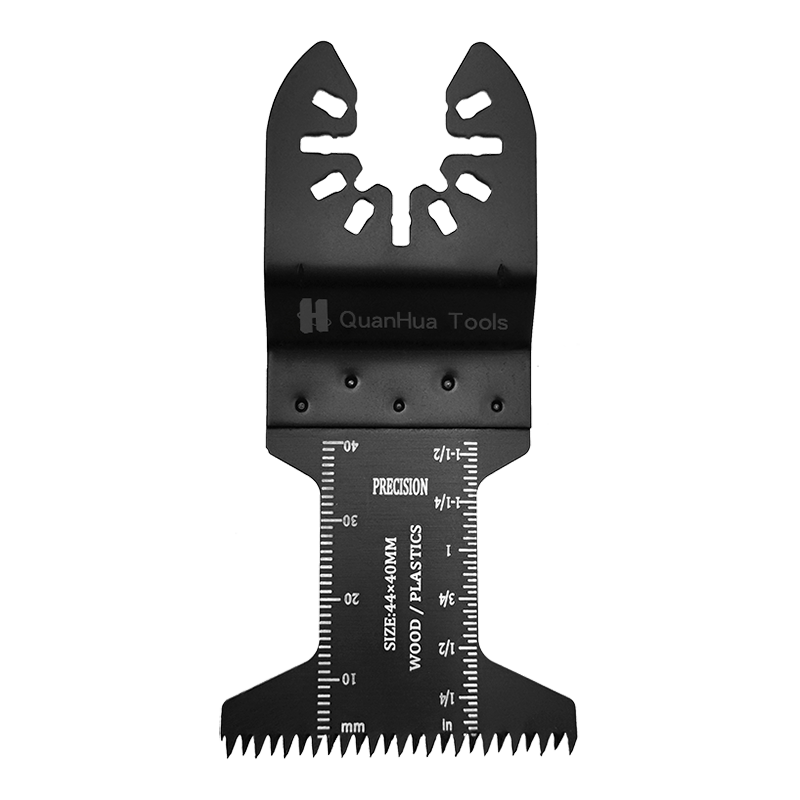

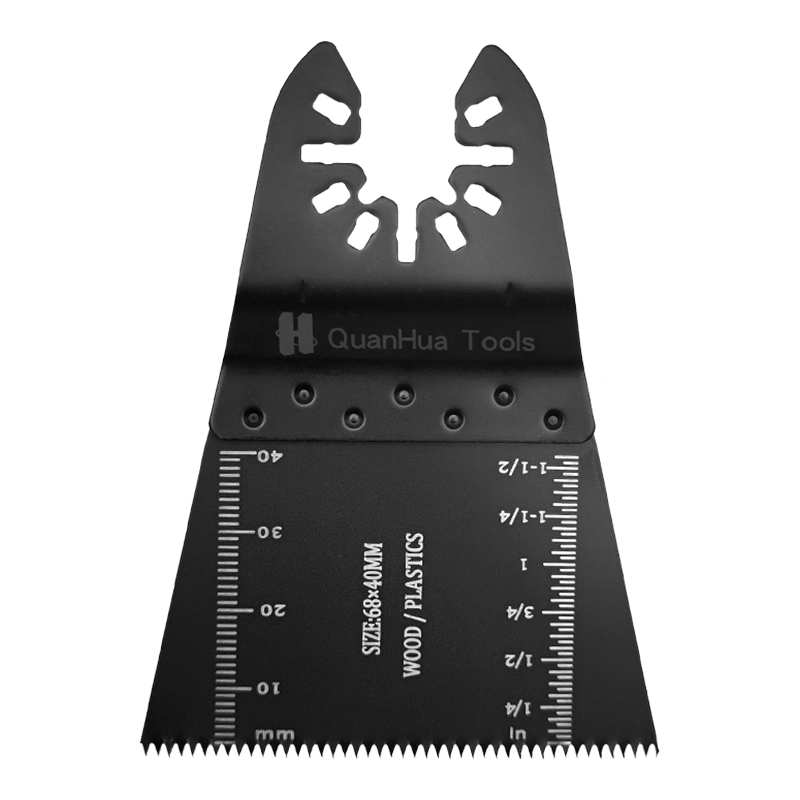

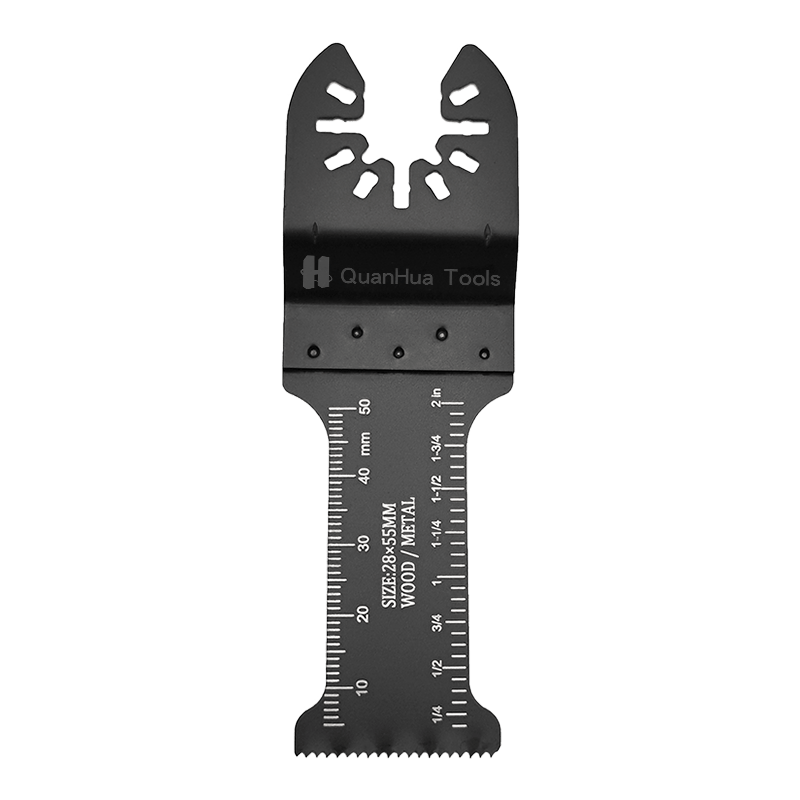

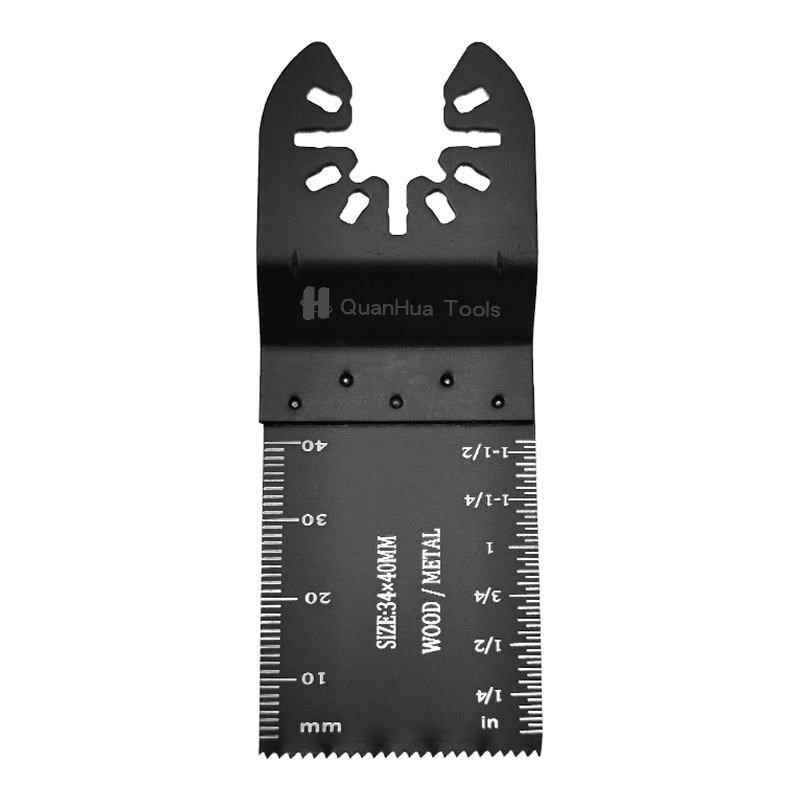

The design of the saw teeth has a direct impact on cutting efficiency. The Carbide Oscillating Multitool Sabre Saw Blade uses carefully designed teeth to ensure that every cut can be completed quickly and smoothly. The arrangement of the teeth has been optimized to minimize the friction generated during cutting, making cutting easier and improving the overall cutting speed. Especially when cutting hard materials such as metal and hardwood, the sharp teeth can easily cut in, reducing the chance of the saw blade getting stuck, thus avoiding interruptions in cutting. The teeth have also been specially hardened to enhance their wear resistance, so that the teeth can remain sharp even in high-intensity continuous work. This optimized tooth design ensures that each tooth of the saw blade is evenly stressed during use, reducing excessive wear of a single tooth and extending the overall life of the saw blade. In addition, the tooth design can also improve the smoothness of the cutting, avoid burrs or cracks on the cut, and reduce the workload of subsequent trimming, thereby further improving production efficiency.

4. Compatibility and ease of operation

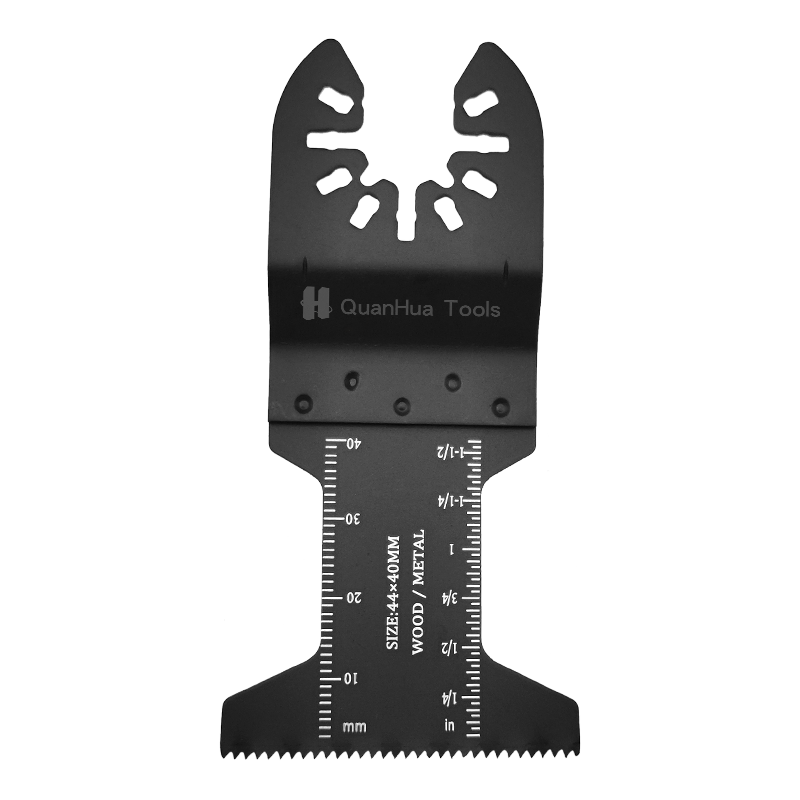

Carbide Oscillating Multitool Sabre Saw Blade is highly compatible with multi-function power tools from all major brands. This compatibility means that users do not need to purchase equipment from a specific brand, and can simply install the saw blade on existing tools. This not only reduces the cost of equipment procurement, but also increases the user's work flexibility. Compatible with multiple tools, users can switch saw blades at any time according to their needs when dealing with different types of materials, greatly improving the efficiency of operation. The installation and replacement process of this saw blade is extremely simple, and it can usually be quickly replaced in just a few steps. This design reduces the workload of operators, allowing them to spend more time on actual cutting work instead of wasting time on tool adjustments. For those working environments that require frequent saw blade changes, simple operation procedures are particularly important, which can significantly reduce downtime and improve overall work efficiency. Not only that, this simple operation process is also very suitable for home users, allowing them to easily cope with daily maintenance or decoration work, and use the tool for precise cutting without professional skills.

5. High temperature resistance and impact resistance

Another significant advantage of tungsten carbide material is its high temperature resistance and impact resistance, which is crucial to improving cutting efficiency. During long-term cutting, ordinary saw blades often soften or deform due to the high temperature generated by friction. Tungsten carbide saw blades have extremely high high temperature resistance and can maintain their hardness and cutting performance in high temperature environments, avoiding performance degradation caused by overheating of the saw blade. In addition, the impact resistance of tungsten carbide saw blades is also very good. Even in the face of high-intensity cutting tasks, it can resist the impact of external forces and maintain stable cutting efficiency. Especially when cutting heavy or hard materials, ordinary saw blades may produce greater stress due to sudden changes in the material, causing damage or even breakage of the saw blade. Tungsten carbide saw blades can withstand such stress shocks to ensure the continuity and safety of the cutting process. This durability not only extends the service life of the saw blade, but also reduces the frequency of replacing the saw blade during the cutting process, greatly improving work efficiency. Under high temperature, high pressure or complex working conditions, the excellent performance of tungsten carbide saw blades makes it the only choice for professional cutting tools.