How to maintain a garden saw blade

Clean regularly

Remove debris: After each use of a garden saw, the blade should be thoroughly cleaned to remove dirt, resin, and gum. The blade can be wiped with a brush or cloth, and deep cleaned with an appropriate solvent or gum remover. If there is stubborn resin or gum on the saw blade, it can be treated with a special resin remover to avoid affecting the cutting performance of the saw blade. Regular cleaning not only maintains the working efficiency of the saw blade, but also prevents the accumulation of resin from causing the saw blade to stick, which affects the use effect.

Dry thoroughly: After cleaning, always dry the saw blade thoroughly to prevent rust. The saw blade can be wiped with a clean cloth to ensure that there is no moisture left. When using the saw blade in a humid environment, try to avoid contact between the saw blade and water, and regularly check the surface of the saw blade for rust. If rust is found, it needs to be treated in time to avoid further damage.

Check for damage

Check for cracks: Regularly check the saw blade for cracks or other signs of damage. These cracks may be caused by excessive use of the saw blade, dropping, or other physical impact. Minor cracks can be treated by grinding and repairing, but serious cracks require replacement of the saw blade to ensure safe use. The good condition of the saw blade directly affects the effect and safety of cutting. Regular inspection and timely replacement can help avoid potential safety risks.

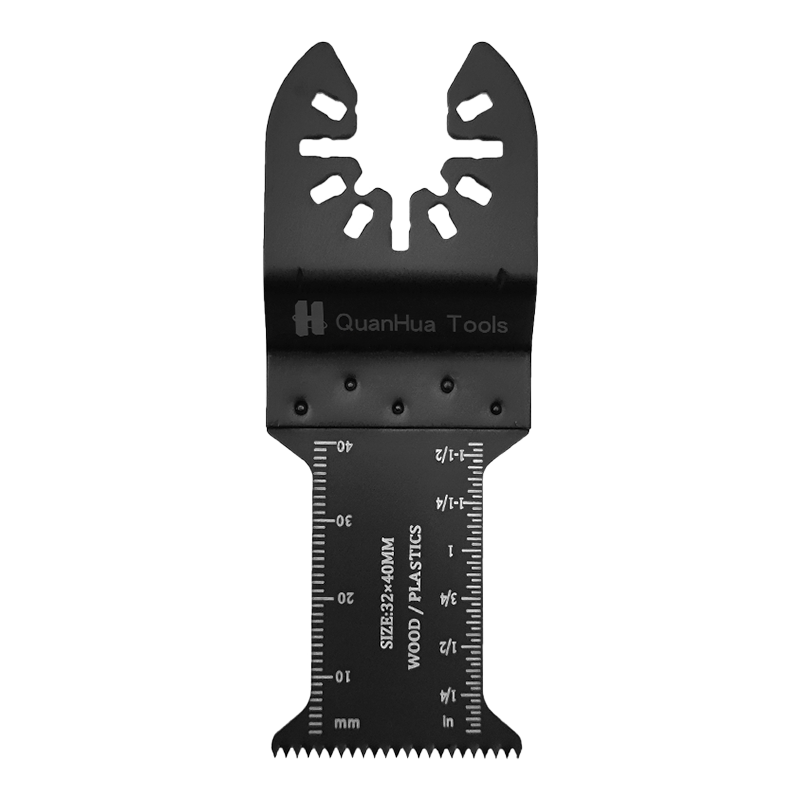

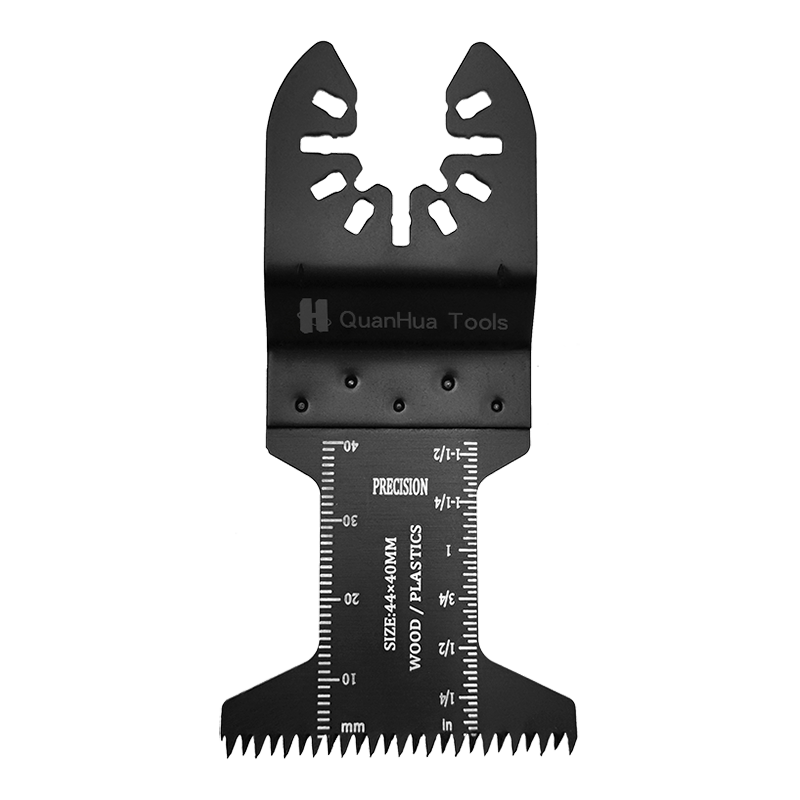

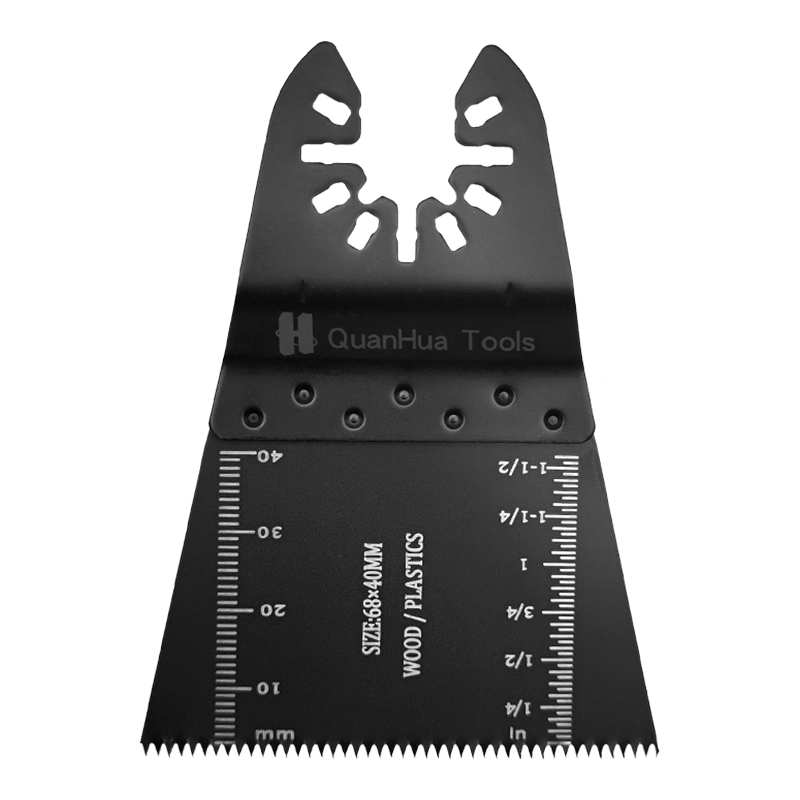

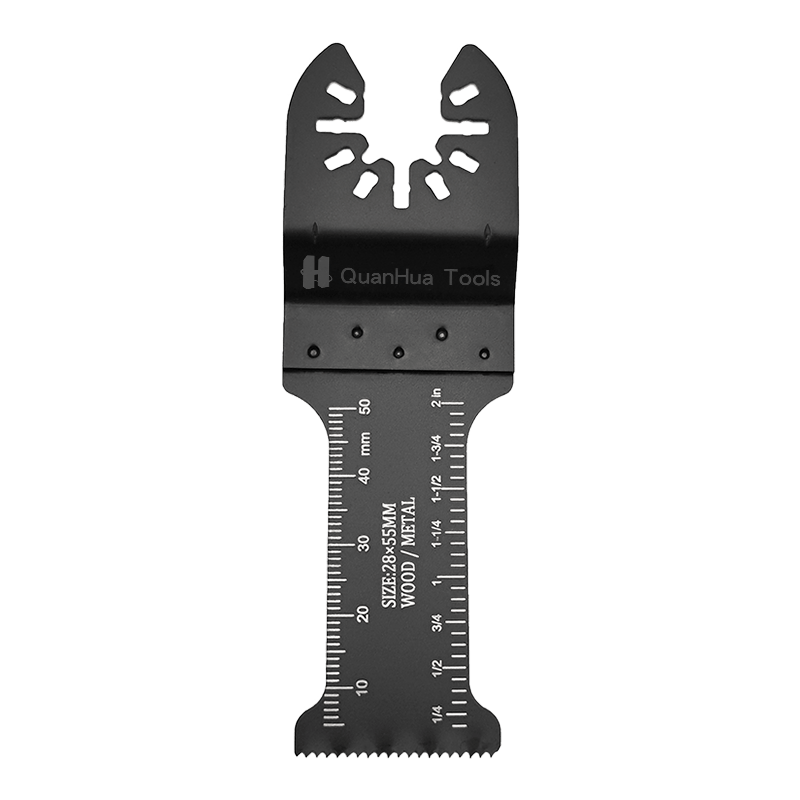

Check the teeth: Check whether the saw teeth are worn or bent. Wear of the saw teeth will cause uneven cutting, increase the workload of the saw blade, and affect cutting efficiency. If the saw teeth are found to be severely worn, they should be re-sharpened or replaced. To maintain the best condition of the saw blade, you can use a saw tooth inspection tool to ensure that each saw tooth is functioning properly.

Proper storage

Store in a dry place: Store the saw blade in a dry environment and avoid moisture. A humid environment can easily cause the saw blade to rust, thereby shortening its service life. The ideal storage condition is a low-humidity, well-ventilated place. If possible, place the saw blade in a dust cover or protective cover for additional protection.

Avoid contact with moisture: Make sure the saw blade is not exposed to moisture or humidity during storage. If the saw blade comes into contact with water during use, it should be dried immediately. Avoid placing the saw blade in a humid environment, such as an uncovered outdoor storage area or basement. By keeping it dry, you can effectively prevent the saw blade from rusting and performance degradation.

Lubrication

Applying grease: Applying a thin layer of grease to the saw blade regularly can effectively prevent the saw blade from rusting. Use a lightweight anti-rust oil or lubricant, such as motor oil or special oil for saw blades, and apply it to the surface of the saw blade. The application of lubricant can form a protective layer to isolate moisture and oxygen in the air, thereby reducing the possibility of rust. After use, make sure to wipe off excess grease to avoid oil stains during cutting.

Keep it clean: After applying grease, wipe the surface of the saw blade with a clean cloth to remove excess grease. Excess grease may adhere to the wood when cutting and affect the cutting effect. The right amount of lubrication can keep the saw blade clean and help extend its life.

How to sharpen a garden saw blade

Choose the right tool

Saw file: For hand saws, use a specially designed saw file. Triangular files are ideal for trimming the teeth. Choosing the right saw file is essential for effective sharpening. Different types of files can be selected according to the type of saw blade and the shape of the teeth. When using the file, keep the file at the same angle as the teeth to ensure even sharpening.

Sharpening tools: For large or special saw blades, sharpening tools or professional sharpening services can be used. Electric sharpeners can improve efficiency and ensure precision sharpening. When using these tools, make sure to follow the manufacturer's instructions to avoid damaging the saw blade. Calibrate the sharpening equipment regularly to maintain optimal sharpening results.

Sharpening process

Securing the saw blade: During the sharpening process, clamp the saw blade firmly to prevent movement. You can use a special saw blade clamp or workbench to fix it. Sturdy fixation ensures precision during the sharpening process and avoids uneven sharpening due to movement of the saw blade.

Saw tooth sharpening: Sharpen each saw tooth one by one, maintaining the original angle of the saw tooth. Use even force to sharpen to ensure that the sharpening effect of each saw tooth is consistent. For crosscut saws, sharpen from the inside of the saw teeth; for rip saws, sharpen from the outside of the saw teeth. Check the sharpening effect regularly and make necessary adjustments.

Check the alignment of the saw teeth

Adjust the saw teeth: Use the saw tooth adjustment tool to check and adjust the alignment of the saw teeth. The alignment of the saw teeth directly affects the smoothness and efficiency of the cutting. If the saw teeth are deflected, the saw tooth adjustment tool needs to be used to correct it. The alignment of the saw teeth ensures smooth cutting and avoids the saw blade from jamming or deflecting.

Correct the alignment: By correcting the alignment of the saw teeth, ensure that each saw tooth is on the same horizontal plane. Reasonable alignment can improve the accuracy and efficiency of cutting. You can use professional alignment tools to check and adjust to ensure the best performance of the saw blade.

Test the saw blade

Cutting test: After sharpening, test the cutting effect of the saw blade on a piece of wood. Check whether the saw blade can cut the wood smoothly and ensure that there are no jams or other problems during the cutting process. If problems are found, further adjustments or re-sharpening may be required.

Adjustment and correction: Make necessary adjustments and corrections based on the test results. If the cutting effect is not ideal, you can re-sharpen or make further adjustments to the saw teeth. Through continuous testing and adjustment, ensure that the saw blade's cutting performance reaches the best state.