1. Understand the material type

The first step in choosing the right bimetal saw blade is to understand the type of material you are cutting. Different materials have different physical properties, such as hardness, toughness, and density, which affect the choice of saw blade. For example, metals with higher hardness (such as stainless steel) usually require harder and more wear-resistant saw blades to cope with the wear during cutting. For soft wood or plastic, you can choose a relatively soft saw blade with a larger tooth shape to achieve fast cutting. In practical applications, it is recommended to study the specific properties of the material before cutting, and even conduct small-scale tests to ensure that the selected saw blade can effectively cope with the required cutting task. This step not only improves work efficiency, but also avoids saw blade damage or material loss caused by improper selection.

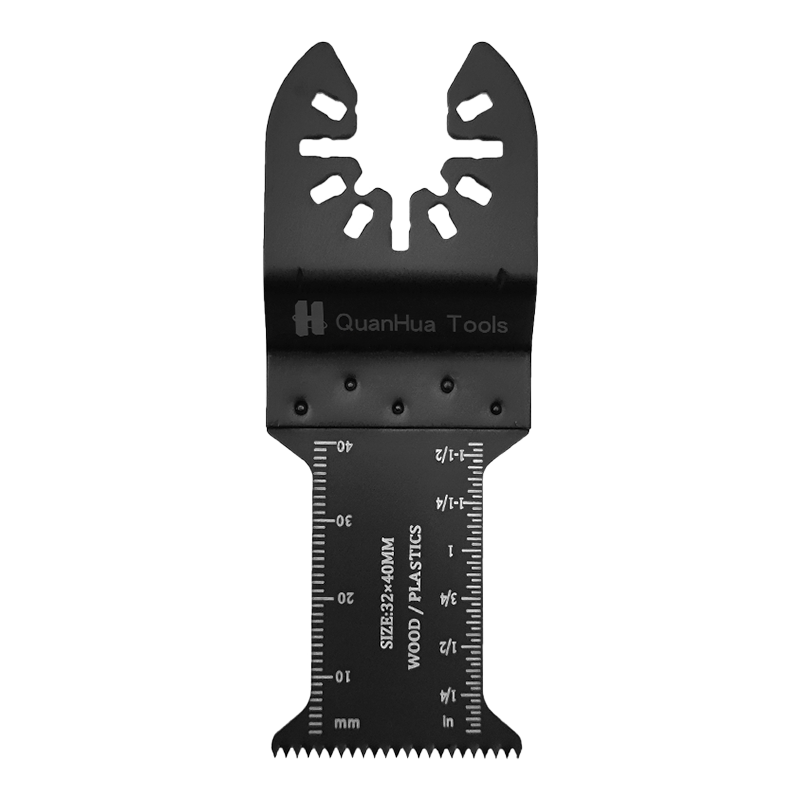

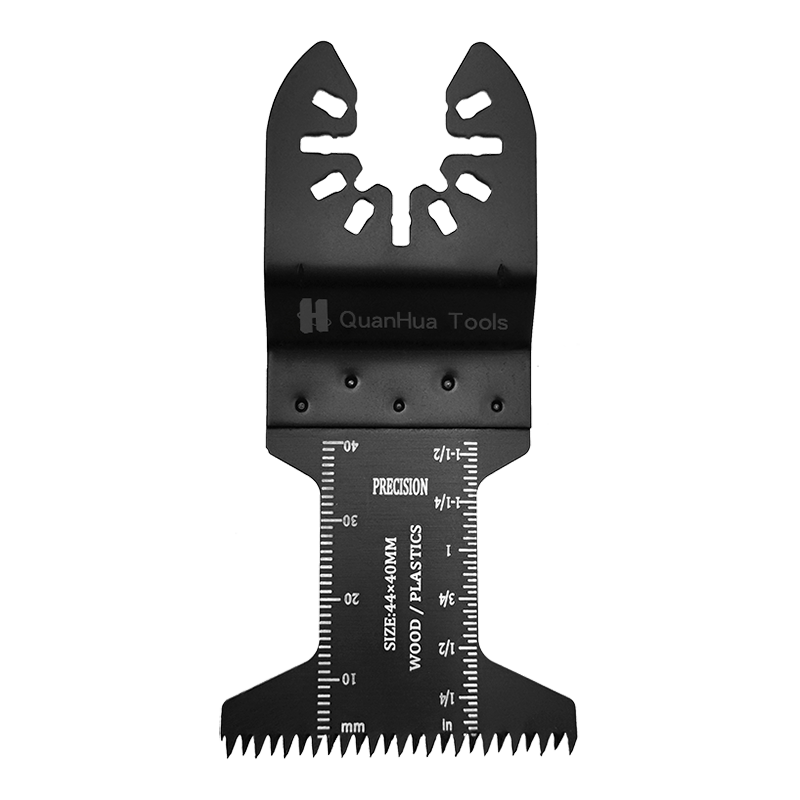

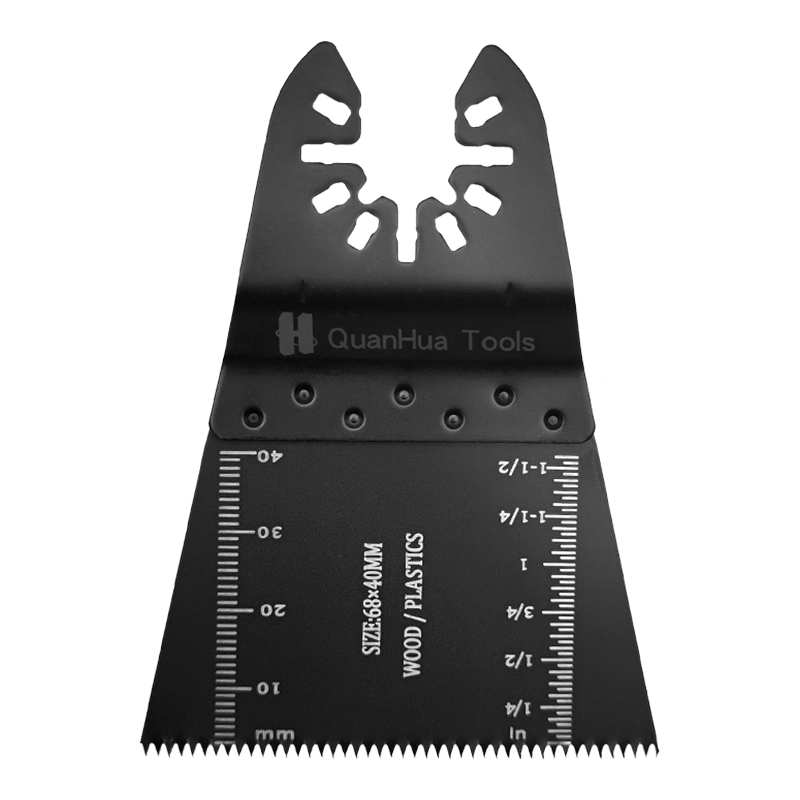

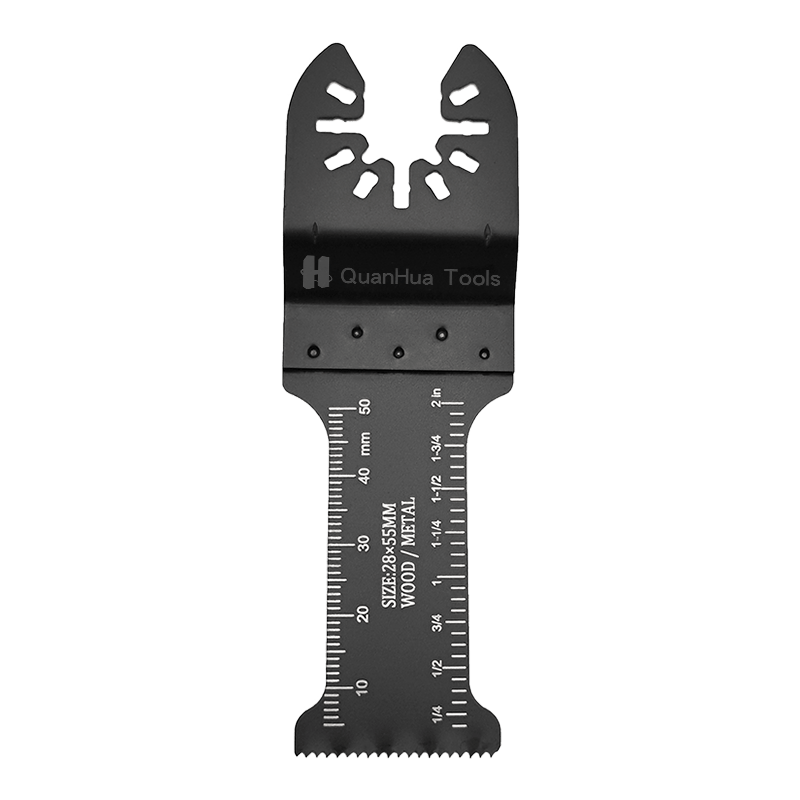

2. Tooth design of saw blade

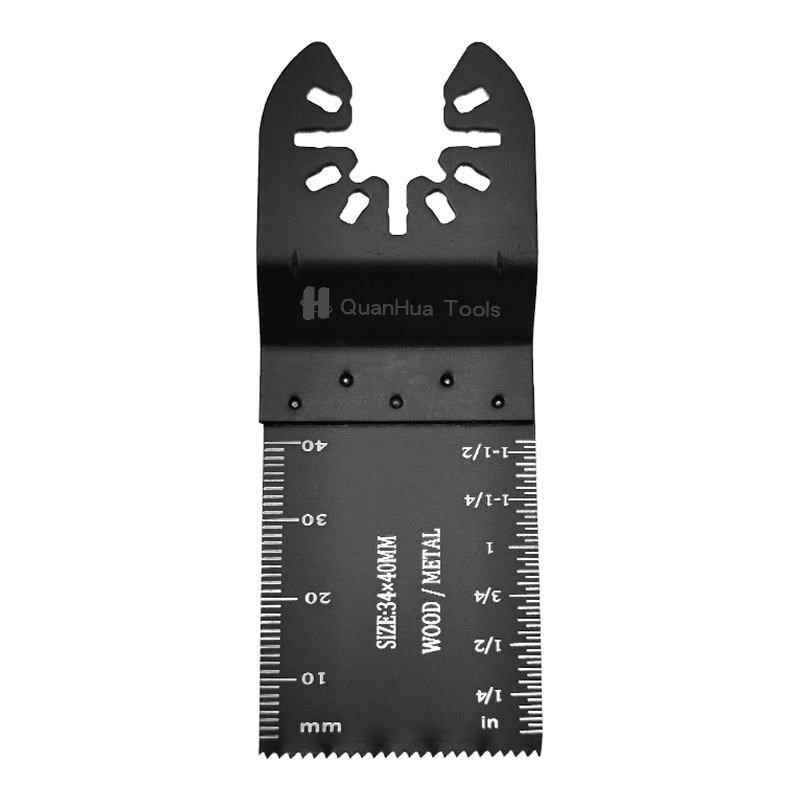

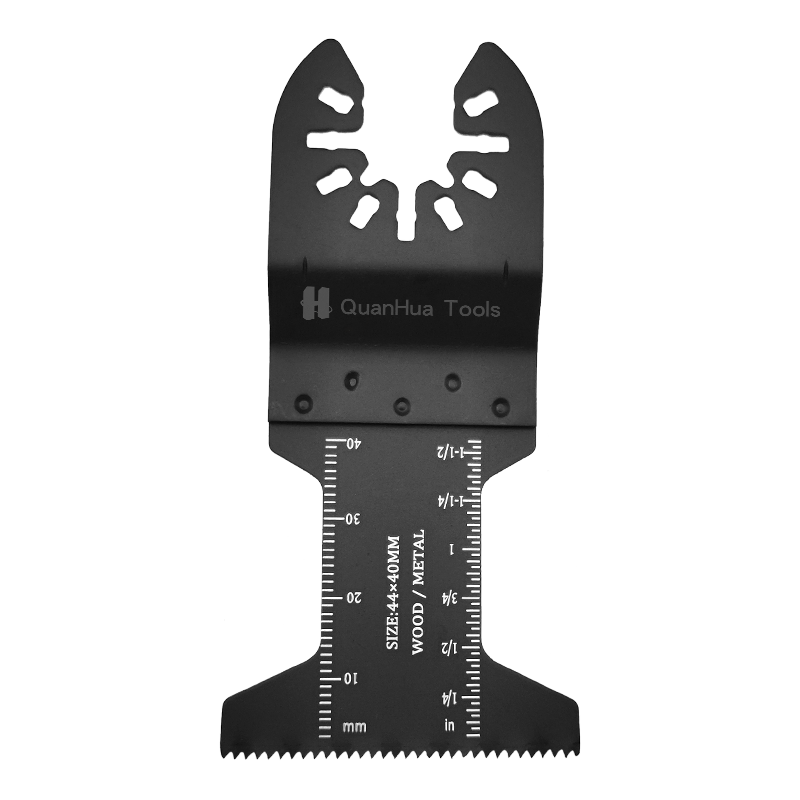

The tooth design of bimetal saw blade directly affects the efficiency and effect of cutting. Different tooth shapes are suitable for different cutting needs. Common tooth shapes include sawtooth type, flat tooth type, and bevel tooth type. The sawtooth type is suitable for rough cutting, can quickly remove a large amount of material, and is suitable for cutting wood and some plastics; the flat tooth type is used for materials that require fine cutting, such as thin metal and composite materials. For applications that require high cutting accuracy, selecting a saw blade with a small tooth pitch and a large number of teeth can effectively reduce the edge burrs generated during the cutting process. By analyzing the characteristics of the target material and combining it with the actual cutting requirements, selecting the appropriate tooth shape can improve the quality and efficiency of cutting and avoid waste caused by improper cutting.

3. Number of teeth and cutting speed

The number of teeth (TPI, or the number of teeth per inch) of the saw blade is an important factor affecting the cutting speed and effect. Generally speaking, the more teeth, the finer the cutting, which is suitable for thin materials such as thin steel plates and plastics; while saw blades with fewer teeth are suitable for rough cutting of thicker materials. Selecting the right number of teeth can optimize the cutting process and achieve the expected cutting quality. For example, for metal materials with a thickness of more than 3 inches, it is recommended to use a saw blade with 4 to 6 TPI to ensure that the material can be effectively removed during cutting while maintaining a good cutting effect. For thin plates and precision work, it would be more appropriate to select a saw blade with 10 to 32 TPI. The cutting speed should also match the number of teeth. A higher cutting speed may cause the saw blade to overheat and shorten its service life. Therefore, a reasonable combination of the number of teeth and cutting speed can achieve efficient and long-lasting cutting results.

4. Material thickness

The thickness of the material is another important consideration when choosing a bimetal saw blade. Thicker materials usually require stronger saw blades to withstand the greater pressure generated during cutting. For example, when cutting steel plates up to 2 inches thick, you should choose a special high-strength saw blade, which usually has a larger tooth spacing and better bending resistance. Thickness also affects the cutting speed and feed rate; when cutting thicker materials, the feed rate should be moderately reduced to avoid overheating or jamming of the saw blade. It is recommended to refer to the manufacturer's recommendations when selecting a saw blade to ensure that the saw blade is used under appropriate cutting conditions to improve work efficiency and reduce the risk of damage.

5. Cutting speed and feed rate

Choosing the appropriate cutting speed and feed rate is key to ensuring that the bimetal saw blade works effectively. Cutting too fast will cause the saw blade to overheat, reduce its performance and life, and may even cause it to break. Conversely, too slow speed will reduce work efficiency. In general, you should adjust the cutting speed according to the hardness of the material and the design of the saw blade. For harder materials, such as hard steel, slower speeds and moderate feeds can effectively prevent overheating, while for soft woods, the cutting speed can be increased moderately. It is generally recommended to make test cuts and record the results to find the best cutting parameters based on the characteristics of the saw blade and the material. This adjustment can significantly improve cutting efficiency and ensure the ideal cutting effect.

6. Consider the coating of the saw blade

Some bimetallic saw blades may be coated with special coatings to improve cutting performance and durability. These coatings are usually used to reduce the friction between the saw blade and the material, thereby reducing the heat generation during cutting and extending the life of the saw blade. Common coatings include titanium coatings and nitride coatings, which not only improve the wear resistance of the saw blade, but also effectively prevent rust and corrosion. Choosing a saw blade with an appropriate coating can help maintain efficient cutting performance under various environmental conditions. Coated saw blades can significantly improve cutting speed and cutting accuracy when cutting metal materials. Therefore, paying attention to the coating characteristics of the saw blade can help you achieve better results in complex cutting tasks.